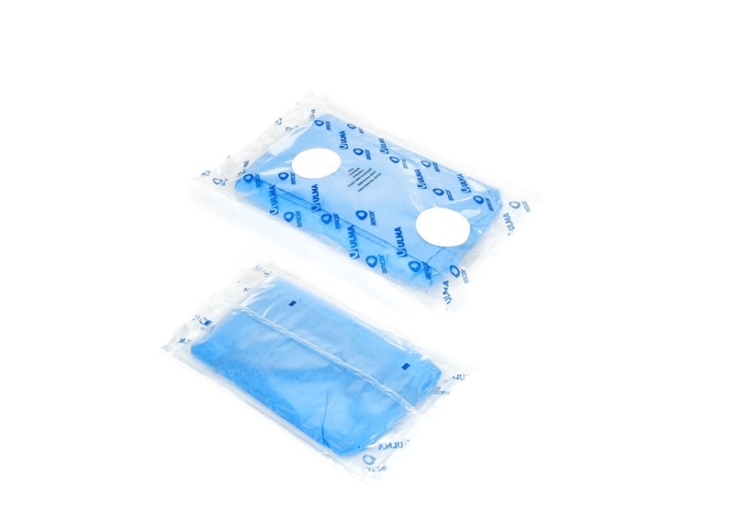

Chevron sealing is suitable for products that require seal integrity on all four package sides

Harpak-ULMA has announced a flow-pack solution capable of applying a chevron seal for medical device packaging (Credit: Business Wire)

Harpak-ULMA, the North American arm of ULMA, has introduced chevron seals for flow-wrapping applications.

The company’s flow-pack solution holds the capacity to apply a chevron seal for medical packaging. The flow-wrapping is said to be one of the most cost-effective methods for packaging high-profile products.

It can also be applied to kits, where one or more devices are contained in an inner wrap that serves as an adequate sterile barrier.

Harpak’s chevron seals with peelable side seals will help enhance ease of opening, and make cost-effective flow-wrapping as a feasible alternative for dimensional, larger, or bulky disposable products that need an easy-to-open seal.

The chevron seals with peelable side seals to improve ease of opening

Chevron sealing is suitable for products that need seal integrity on all four package sides. It is also in line with recently updated ISO 11607 guidelines that indicate the use of aseptic presentation of terminally sterilised medical devices.

The company has exhibited the flow-wrap chevron sealing samples at this year’s MD&M West conference.

Harpak-ULMA CEO Kevin Roach said: “Harpak-ULMA is committed to continuous innovation across all of our packaging platforms. We expect that introducing chevron seal capabilities in our flow-wrapping solutions will be well-received by medical device customers seeking affordable, compliant packaging options.

“Thought leadership is not just about envisioning the future for customers, it means executing on it. We are expanding the depth and breadth of options available to our customers on every front – from sealing technology to smart connected machines and even augmented reality.”

In January this year, Harpak-ULMA developed new flow wrapper, ULMA FS-400, for packaging raw food products such as fresh poultry and meat.

The FS-400 flow wrapper has been designed to produce cost-effective, leak-proof trayed packaging for raw food products that vary in size and shape.

Harpak-ULMA offers smart and connected packaging systems for food, medical, bakery, and industrial products.