Ryder’s new e-commerce fulfillment center near Philadelphia is a 340,000-square-foot food-grade facility, and it is scheduled to begin the integration of automation technology this summer

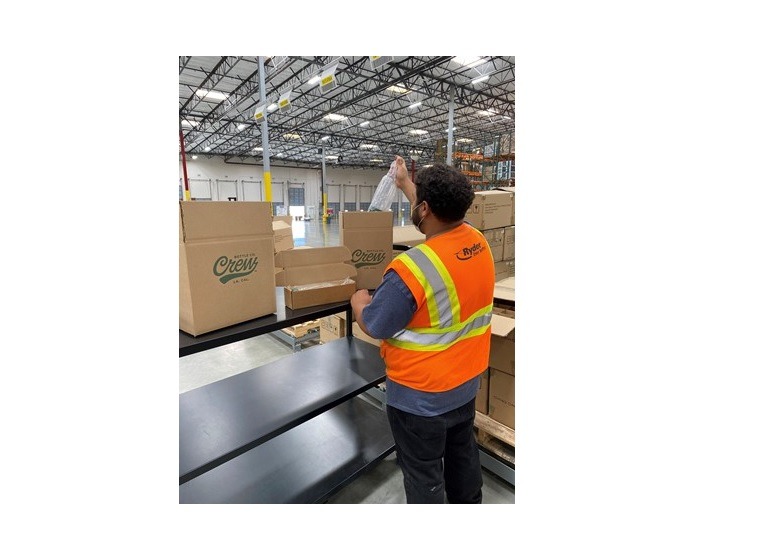

Ryder has expanded e-commerce fulfillment network with food-grade capabilities and additional locations. (Credit: Business Wire)

Ryder System, a leader in supply chain, dedicated transportation, and commercial fleet management solutions, today announced that it has added food-grade capabilities to its e-commerce fulfillment network, including a new facility near Philadelphia, as well as added food grade capabilities to two additional facilities within the network to meet evolving consumer buying trends.

“Now more than ever, people have become even more comfortable with ordering just about everything online,” says Steve Sensing, president of global supply chain solutions for Ryder. “With that trend expected to continue, our customers recognize the need to diversify their supply chains and the channels they use to take their products to market. They also want the flexibility to respond to surges in demand due to unexpected events or planned seasonality. People want the goods they rely on every day and they want them delivered to their homes in a timely manner.”

Ryder’s new e-commerce fulfillment center near Philadelphia is a 340,000-square-foot food-grade facility, and it is scheduled to begin the integration of automation technology this summer. The automation will allow Ryder to scale the operation to fulfill more than 70,000 packages a day with future expansion of more than 136,000 packages in a three-shift operation. Ryder has also obtained FDA-certification for two other food-grade e-commerce fulfillment facilities near Los Angeles and Dallas, both of which originally opened in early 2019. The additions of these certifications within the network have benefited customers like Rise Gardens and Crew Bottle.

“With more people wanting easy access to safe, fresh food, the sales of our smart indoor hydroponic gardens have grown by 750% since January; and, even with that kind of expansion, Ryder was able to help us scale to meet demand and keep our customers happy,” says Diego Blondet, head of product and strategy for Rise Gardens. “We also have a partner that makes food safety a top priority. Ryder’s food-grade facilities ensure that our customers not only get their products as quickly as possible, but safely.”

“At Crew, we develop hygienic, sustainable bar supplies for hotel chains, craft bars, cocktail enthusiasts and everyone in between. What our customers share is a commitment to guest safety – now more than ever,” says Marshall Sterling, chief operations officer for Crew Bottle Co. “We manufacture our barware from Craft Tech® Glass with strict safety standards in mind, which is why Ryder has been such a valuable partner. We’re confident in the food-grade regulations at their e-commerce facilities and their ability to scale with us as we continue to grow.”

In addition, utilizing existing locations within the well-established Ryder Last Mile network, which had been reserved for big-and-bulky items, Ryder has been able to expand its e-commerce fulfillment network for parcels by 167%. The facilities are located in the Seattle, Chicago, Atlanta, Kansas City, Mo., and Tampa, Fla. areas. Ryder e-commerce customers also have the added benefit of utilizing the nearly 100 locations within the Ryder Last Mile network for cost-effective front-door delivery of parcels that package delivery companies now consider too large and, therefore, apply hefty surcharges.

With Ryder e-commerce fulfillment and last-mile facilities strategically located throughout the U.S., Ryder customers can reach up to 99 percent of the population in two days or less.

Source: Company Press Release