With a capacity to produce 200 packs per minute, the new line has the capacity to work with a variety of product sizes

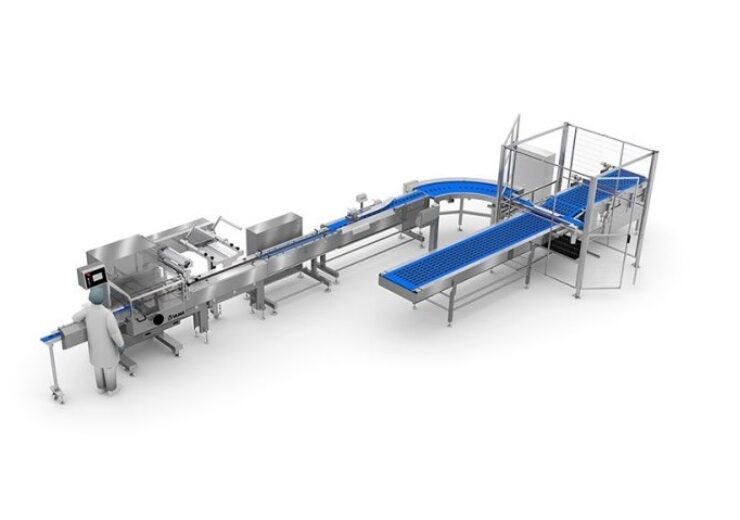

ULMA Packaging has unveiled new automatic packaging line for bars and baked goods. (Credit: ULMA Packaging)

Packaging equipment and services provider ULMA Packaging has unveiled a new automatic packaging line for bars and baked goods.

With a capacity to produce 200 packs per minute, the new line includes a receiving conveyor to sort and line up the products for subsequent even and continuous distribution to one or more packaging machines.

The products are distributed on a swivel conveyor, which places the rows of products on another and subsequent conveyor. They can also be shifted to an accumulation conveyor or a reject conveyor if there is any defect.

An accumulation or buffer conveyor can be optionally installed if there is an issue on the packaging line. It will help the system to transfer the remaining rows to that accumulation conveyor, and later they are automatically shifted back to the wrapper when it detects a gap.

The feeder of the FR 200 flow pack wrapper delivers the products to the packaging machine evenly. The new line has the capacity to work with a variety of product sizes.

With advanced interconnected manufacturing features, the UPC 4.0 enables to connect to the machine remotely, analyse and monitor OEE and view operating instructions and videos.

In June this year, ULMA Packaging introduced VTC 800-R continuous vertical wrapper for the food industry. The new machine is equipped to produce zipper packages at a speed of up to 60 packages per minute.