Bobst, a provider of equipment and services to packaging and label manufacturers, has unveiled PECVD SiOx solution for barrier films.

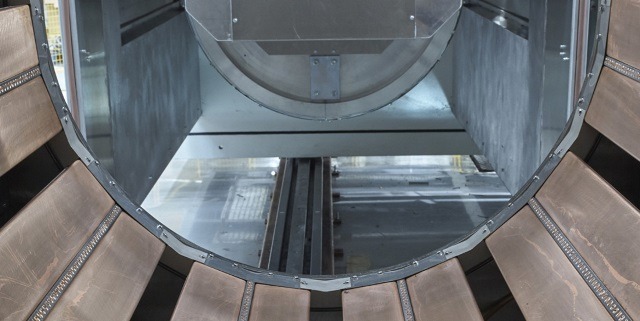

Image: Bobst PECVD SiOx solution produces high barrier film with high degree of transparency that is both retortable and microwavable. Photo: courtesy of BOBST.

Bobst PECVD SiOx solution enables to produce high barrier film with a high degree of transparency, which is both retortable and microwavable.

SiOx coated substrates will induce less problems during the conversion process compared to other transparent barrier films. It is also a suitable solution for converters looking to contribute to circular economy, as it is recyclable and FDA-approved product.

Bobst has commercialized the cost effective PECVD process, which is an operator independent that enables to produce consistent high quality film.

The process integrates the use of a silicon based monomer (HMDSO) that is deposited on to the substrate within a low temperature plasma environment.

The monomer and process gasses will be launched into the vacuum chamber through a form of gas bar, which facilitates even process gas distribution across the width of the machine.

Bobst PECVD process enables to produce very thin films. The quality of the coating will be optimized to achieve better barrier levels.

Due to AC power supply, the physical bombardment of ions and electrons towards the process drum will happen to create densification of Silicon Oxide on to the film, helping to offer resistance to oxygen and water permeation.

The temperatures used across the process are low, making it suitable for heat sensitive and thin gauge substrates such as BOPP and CPP.

SiOx coated film will have better oxygen and water barrier levels of around 2cc/m2/day (OTR) and around 2gm/m2/day (WVTR) on PET and maintains high levels even when subjected to a Stretch-durability test.

The film holds capacity to handle a high level of strain and stretch maintaining barrier at strain levels of less than 4%.

Bobst SiOx process also has efficient adhesion properties for both dry and wet applications. The PECVD SiOx process is provided on the Bobst K6 platform.

The K6 machine integrates two coating drums and is also provided together with the CO 1000 coating machine from Bobst Italia as an integrated SiOx conversion solution.