The Servo Belvac Necker is said to have the capacity to continuously operate up to 3,600 cans every minute using advanced servo motor control that enables every turret to rotate independently

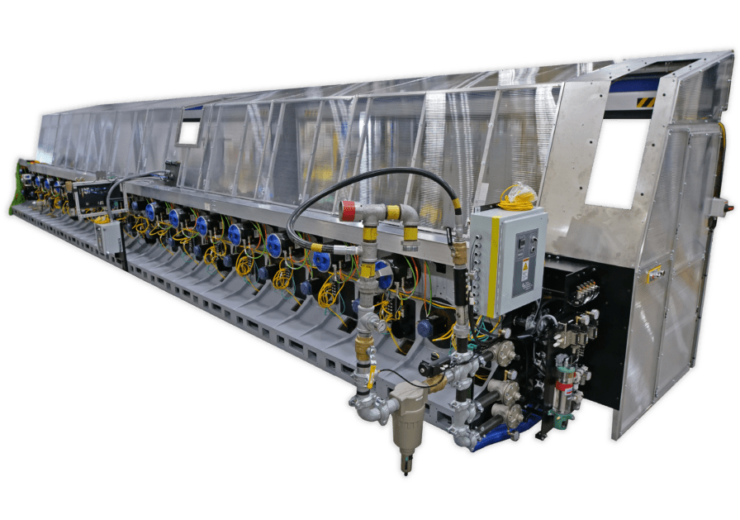

The Servo Belvac Necker. (Credit: Belvac)

US-based two-piece metal packaging supplier Belvac, part of Dover, has introduced its latest development in can necking technology, the Servo Belvac Necker.

The Servo Belvac Necker is said to have the capacity to continuously operate up to 3,600 cans per minute.

The can necking technology uses advanced servo motor control to enable every turret to rotate independently.

The independent rotation is said to resolve can jam situations quickly and facilitates faster resetting and synchronisation, thus increasing efficiency.

Belvac Global Sales Operations director Eric Hodge said: “The Servo Belvac Necker marks a new generation of energy-efficient machinery for the two-piece aluminium packaging industry.

“With the growing industry demand for sustainable technology, the Servo Belvac Necker has been engineered to maximise the profitability of can plant operations.”

According to the metal packaging supplier, the Servo Belvac Necker has 15% less electrical consumption compared to the conventional motor and gearbox configuration on a traditional necker.

Belvac president David Mammolenti said: “Belvac has invested significantly in value engineering the machine, which addresses our customers’ need for more sustainable technology. We look forward to showcasing the machine to the industry at METPACK.”

In March 2021, Belvac announced an investment in the latest fully functional and two-piece can pilot line to expand its container and engineering services.

The firm said that the new pilot line will allow the expansion of capabilities and offerings to meet the demand for beverage can-making equipment and support services.

Founded in 1962 in Virginia, Belvac is part of Dover since 1993.

Based in Illinois, Dover is a global manufacturer and solutions provider. The company provides equipment and components, consumable supplies, aftermarket parts, software and digital solutions, and support services.