Agilyx will preprocess the collected EPS and supplies it to Regenyx advanced recycling facility

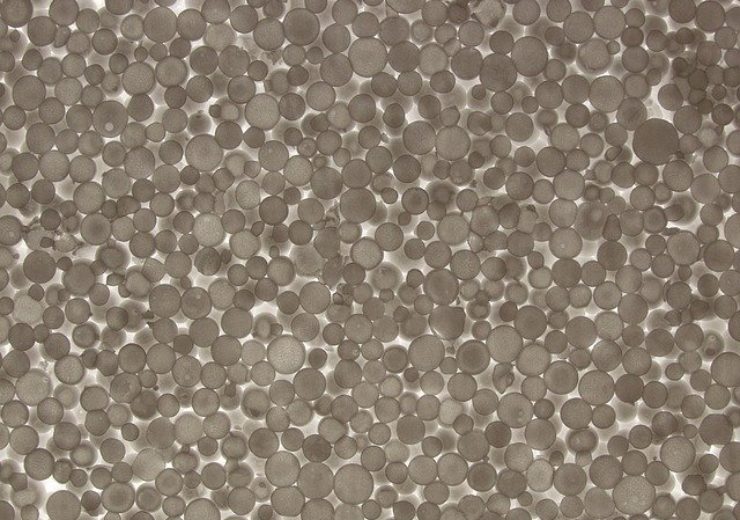

Agilyx and Oregon Metro have collaborated on polystyrene foam collection programme. (Credit: LiesbethStemkens from Pixabay)

Agilyx has collaborated with US-based regional government group Oregon Metro to launch a polystyrene foam collection programme.

Under the pilot programme, the polystyrene foam will be incorporated at the Metro South Transfer Station and recycled back to new material by applying Agilyx’s technology.

Situated at 2001 Washington St of Oregon City, the Metro South Transfer Station takes the responsibility to collect the clean Expanded Polystyrene foam (EPS) packaging at their recycling area.

EPS is generally used in appliance, electronics and furniture packaging applications

EPS, which is generally used in appliance, electronics and furniture packaging, will be collected via the programme.

Metro South superintendent Penny Erickson said: “We serve over 250,000 self-haul customers in the greater Portland region every year. And every year, we have been asked to recycle Styrofoam.”

Agilyx will preprocess the collected EPS and supplies it to Regenyx advanced recycling facility in Tigard, Oregon. Regenyx is a joint venture between Agilyx and Americas Styrenics.

The pilot programme will allow residents of greater Portland to take part in the Circular Economy for plastics by facilitating to convert end-of-life plastics into plastics and avoid entering into the landfills.

According to Agilyx, the new polystyrene items produced using the advance recycled EPS at Regenyx will include up to 70% lower carbon footprint compared against the virgin plastics.

The current pilot programme will serve as a model to develop additional collection programmes across greater Portland and further enhance plastic recovery by increasing access to drop-off facilities.

Agilyx CEO Joe Vaillancourt said: “We are proud to be working with Metro, a governmental group that is focused on providing their constituents environmentally-focused programs to re-think end-of-life plastics.”

Earlier this month, Mitsubishi Chemical subsidiary Lucite International (LI) has collaborated with Agilyx to advance the circular economy for Polymethyl methacrylate (PMMA).