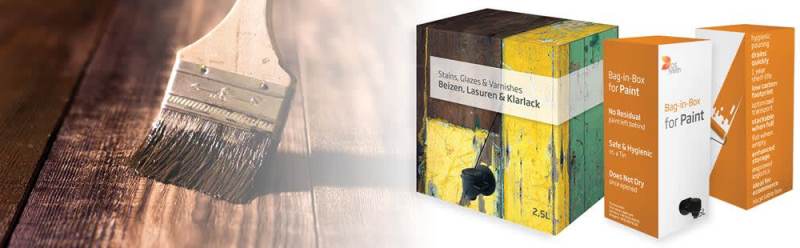

Liquid packaging solutions provider Rapak, which is part of DS Smith Plastics, has launched new Bag-in-Box packaging for paint and varnishes at the European Coatings Show.

Image: Rapak and ACC Beku Introduce Bag-in-Box Packaging for Paint and Varnishes. Photo: Courtesy of DS Smith.

Statistics behind used paint are shocking: according to AkzoNobel ReColour report, 13% of paint is wasted every year and 99% of that paint is either burnt or buried in landfills. There has been a lot of effort by the industry to find ways to reuse or recycle paint and to reduce the amount of product thrown away to a minimum. For now, any packaging that has been in contact with paint is classified as hazardous waste and is sent to incineration. To help reduce the amount of contaminated packaging to a minimum, DS Smith Plastics, Rapak has designed a Bag-in-Box packaging solution for paint.

In the new Bag-in-Box for paint, the only part in contact with the product is a thin and resistant flexible bag which is 50% lighter than tin cans and uses 76% less plastic than HDPE jerrycans of the same size. The outer cardboard box that protects the bag during the transport and handling is made of recycled material, is foldable and 100% recyclable. In terms of CO2 emissions, the new packaging represents only a 10% carbon footprint of aluminum cans of the same size, drastically optimizing the logistics thanks to its perfectly square shape.

The innovative Bag-in-Box packaging solution also tackles the problem of paint waste directly as the air-tight bag prevents the paint, varnish or coating from drying up for as long as 1.5 years after opening. This allows consumers to pour just the right amount and keep the rest for later without worrying about a crust forming on the top of the product. The bag allows 99% product evacuation, which means that all content can be used until the last drop.

DIY activists will also appreciate the convenience of the new Bag-in-Box packaging and little clean-up time. Bag-in-Box packaging can be equipped with a handy dispensing system that allows one-hand serving and ensures no product leaks, splashing or glugging. Once the flexible bag is empty, it is still clean on the outside and it uses very little space, reducing disposal effort and cost.

Rapak (UK), a global manufacturer of Bag-in-Box flexible packaging with 40 years of experience, and ACC BEKU (Germany), a family-owned specialist for toll manufacturing and contract filling of chemical products, will present the breakthrough solution together at the EU Coatings show 2019.

Source: Company Press Release.