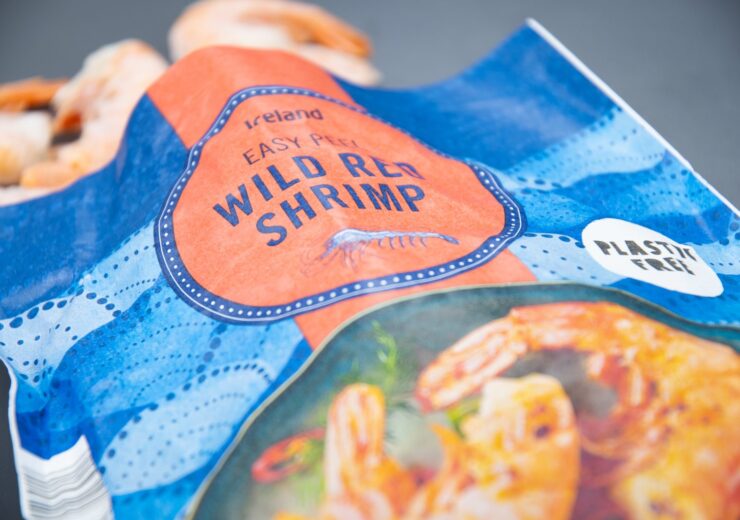

The new sustainable solution has been designed for the supermarket’s Northcoast line of frozen seafood

Parkside and Iceland collaborated to deliver paper recyclable packaging solutions for frozen food. (Credit: Parkside Flexibles Ltd)

Sustainable, flexible packaging solutions provider Parkside has collaborated with Iceland to deliver paper recyclable packaging solutions for frozen food.

The new sustainable solution, claimed to be the first of its kind, has been designed for the supermarket’s Northcoast line of frozen seafood.

It is said to be an important milestone for both Iceland – in its goal of plastic-free packaging – and the frozen food industry as one of the first successful uses of paper flexible packaging.

Iceland packaging specialist Mark Armstrong said: “As everyone knows, we are loud and proud about our forward-thinking ideas and commitment to plastic-free packaging across our products.

“We previously worked with Parkside in a successful bid to reduce food waste via a lidding film solution in 2017. But we know we can do more.

“As consumer sentiment continues to grow for circular solutions, it is the perfect time to collaborate once again in a bid to reduce unnecessary plastic in our packaging.”

The Northcoast products of Iceland are now packaged in a specifically designed recyclable paper pouch with high grease and oil resistance rather than their old LDPE bag packaging.

The heat-sealable paper solution has been designed to resist prolonged exposure to moisture and frost in a freezer environment.

This has been achieved by using a variety of water-based coatings with high barrier performance that are created to degrade when re-pulped in the paper recycling process, as well as good heat saleability.

Parkside sales account manager Mark Shaw said: “It has been a huge privilege for us to work on this project with Mark and his team. Until recently, achieving a high level of grease and oil resistance and heat seal ability for frozen food has been extremely challenging.

“Typically, a plastic layer such as Polyethylene would need to be extruded or laminated to the paper, which would then need to be removed when recycling post-consumer use.

“Our leading technology removes the need for the plastic and gives a truly recyclable paper solution with the added benefit of high barrier functionality.”