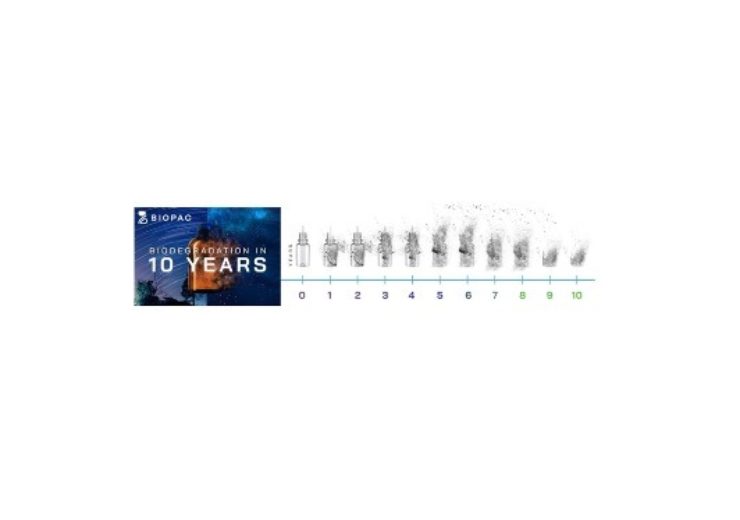

BioPAC is Lifestyle Packaging’s advanced formula designed help degrade plastic packaging in 10 years

Lifestyle Packaging has introduced BioPAC formula for plastic packaging biodegradability. (Credit: Lifestyle Packaging)

Yorkshire-based packaging specialist Lifestyle Packaging has introduced an advanced formula for the biodegradability of plastic packaging in the UK market.

The formula, dubbed BioPAC, will help degrade plastic packaging in 10 years, which is 100 to 200 times faster than the natural lifespan of plastic.

Lifestyle Packaging’s advanced plastic additive has to be added to the base polymer such as polypropylene (PP), polyethylene (PE), polystyrene (PS), polyethylene terephthalate (PET) to improve the biodegradability without applying UV or high temperatures.

The advanced formula enables acids, secreted naturally by more than 600 microbes, to lighten the macromolecules within the plastic for quicker biodegradation.

According to the company, the plastic also remains recyclable where accepted by local recycling schemes.

The plastic will be converted into CH4, CO2, biomass, and water if the product ends its lifecycle in anaerobic systems such as landfills. The CO2, biomass, and water are produced in aerobic systems such as compost facilities.

The advanced formula will not disturb the physical properties of the plastic packaging

The formula will not have any impact on the physical properties of the plastic packaging, allowing products to maintain their normal shelf life and tensile strength. In addition, the packaging is also food and body safe.

Lifestyle Packaging’s in-house packaging technologists will coordinate directly with brands across the CBD, vaping, fragrance and personal care industries for the development of customised plastics with optimised biodegradability.

The company’s team is also having expertise in bottle jar decoration and labeling, child-resistance, concept and prototyping, and commercial production.

Lifestyle Packaging global marketing head Rich Quelch said: “Plant-based polymers were initially considered as a sustainable solution to plastic waste, however their properties meant packs degraded prematurely, and usability and functionality were unduly affected.

“We believe BioPAC will help solve this problem without affecting packaging design and functionality.

Recently, Kraton, a provider of specialty polymers and biobased products, has introduced new REvolution rosin ester technology for biobased products.