Komori’s press replaces two older presses and delivers enhanced production capacity than the two older presses combined

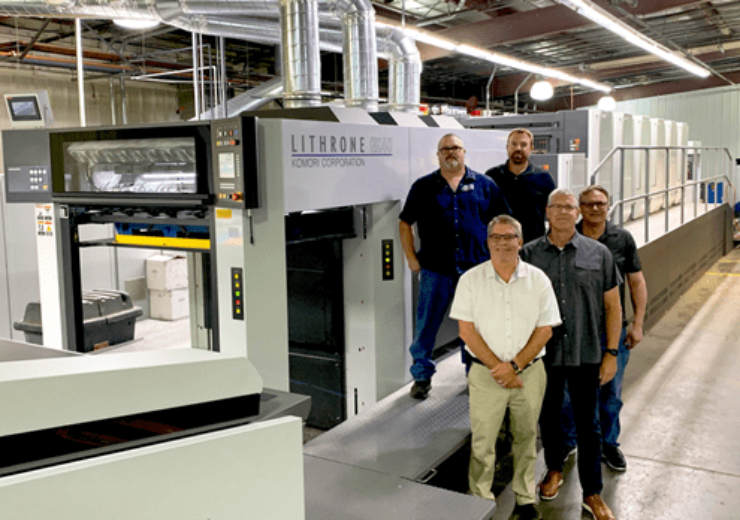

OlymPak Printing & Packaging has installed Lithrone GX40 press. (Credit: Komori America Corporation)

OlymPak Printing & Packaging has installed a new Komori six-colour, 40-inch press called the Lithrone GX40 (GLX640) to boost the capabilities of the folding carton production.

The new Komori press replaces two older presses and delivers enhanced production capacity than the two older presses combined.

The advanced automation of the new press allows OlymPak to improve the flexibility required for its expanding packaging business.

Komori’s press has been purchased by OlymPak to meet the increased packaging requirements of the company’s high-end retailers.

The new machine consists of multiple features, which will help handle several types of package printing.

The machine includes an 18,000 sheets-per-hour (sph) workhorse with fully automated makeready, which includes auto plate load and all washup functions.

In addition, the press features the Komori AI software package that assessed which settings were effective last time and then uses the same settings in the next job.

OlymPak Printing & Packaging company president Mark Miner said: “Initially, we thought a digital press would be the best solution to handle our short-run work.

“However, as we analyzed our return on the investment, we immediately saw the Komori GLX640 as the clear choice. The press can manage both short and long runs and offers amazingly fast changeovers. The speed and efficiencies built into this press will pay for itself in just the time savings alone.”

OlymPak Printing & Packaging, which is a division of MinMor Industries, operates packaging facilities in Mora and Grand Rapids of Minnesota.

The company serves customers in different industries such as retail packaging, nutraceuticals, food and foodservice, beauty and personal care, in addition to major retailers such as Walmart, Target and CVS.