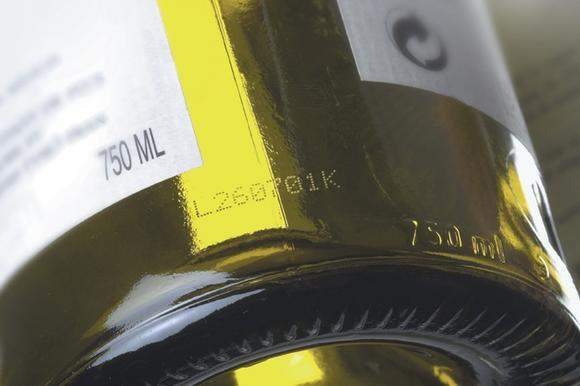

The bottles at O-I are laser coded on the base ...

Laser equipment from Linx Printing Technologies believed to be a glass sector first which allows coding directly onto newly formed bottles while the glass is still hot has been installed on six production lines at UK glass packaging manufacturer O-I’s Harlow plant.

“We needed to ensure the container code was easily distinguishable from the information used by the filling company to identify the batch or use by date,” says O-I quality assurance manager Mark Eldrett. “We also needed a durable solution able to withstand the filling and distribution process. Linx recommended its hot glass coding laser solution.”

Linx says laser coding while the glass is still red hot. generates a very “clean” smooth mark.

To cope with temperatures of up to 650 degs C on newly formed bottles and ambient temperatures near the production line of 70 degs C, Linx supplied O-I with several specially developed Xymark BBH laser coders adapted for the hostile environment.

Each coder at O-I applies single alphanumeric codes at 50 metres/min, indelibly marking date and time of manufacture onto the bottle base.