The 140ppm AccurioPress C14000 and the 120ppm AccurioPress C12000 were unveiled at the event

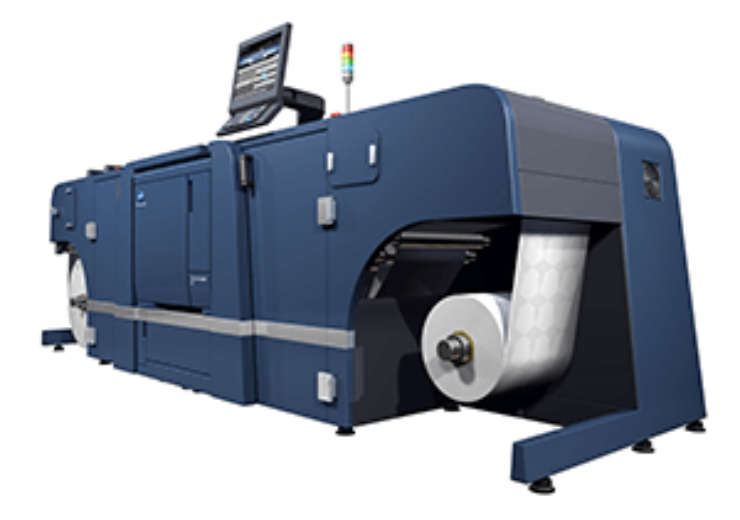

Image: The Konica Minolta’s AccurioLabel 230 machine. Photo: courtesy of Konica Minolta Business Solutions (Canada) Ltd.

Konica Minolta Business Solutions (Canada) (Konica Minolta) a printing technology firm, used the stage of the industry’s largest show to introduce five new products. Starting with the worldwide premiere of the AccurioPress C14000, its new high-volume, toner-based production press and fastest model yet, a new digital label press, digital embellishment press, desktop multi-purpose embellishment solution and a corrugated box printer all made their U.S. debut last week during PRINTING United in Dallas, Texas.

“With the introduction of these new industrial and production print units, we’re once again demonstrating why Konica Minolta has earned a reputation as an innovator and industry leader,” said Chris Dewart, President and CEO, Konica Minolta Business Solutions (Canada) Ltd. “These products offer value to print operations of all sizes. We’re investing in technology that covers the entire spectrum of graphic communications and industrial print capabilities, and which are specifically designed to generate new and expanded streams of revenue for our customers.”

AccurioPress C14000 – High-volume, toner-based production press

The 140 ppm AccurioPress C14000, along with the 120 ppm AccurioPress C12000, were designed from the ground up to be digital print factories. The products demonstrate Konica Minolta’s mission to support the transformation of its clients, creating solutions together that expand and streamline their businesses through advanced automation, fewer human touchpoints and higher productivity with tangible effect leading to increased, high-quality output with less waste.

The unique features of the AccurioPress C14000 series make these products ideal for customers looking to increase productivity through efficiencies and speed to grow their business. With resolution equivalent to 3600×2400 dpi and enhanced media capability up to 450 gsm, these new products offer breathtaking speeds with outstanding image quality and unparalleled media flexibility. Paired with Konica Minolta’s enhanced IQ-501 Intelligent Quality Optimizer, the new presses automatically and continuously measure and correct colour so the first print in a run matches the last. Two-dimensional registration correction has also been improved through the higher output resolution.

AccurioShine 101 – Desktop multi-purpose embellishment solution

The AccurioShine 101 offers specialized embellishment finishing effects in combination with Konica Minolta production printers, as well as a small footprint, affordable price point and several multi-coating functions. This desktop solution, with its simple, quick job setup process makes embellishment available in-house at a printer’s fingertips. Benefits include high value-added printing and high quality CMYK overprint on foil. Special effects include toner foiling, metallic colour foil, lamination films and spot gloss highlights. Easy operation enables short lead times for in-house added-value print services and the affordable price allows users to bring a special “bling” to projects.

AccurioLabel 230 – In-house label production

Konica Minolta’s AccurioLabel 230 is the latest version in its toner-based digital label press portfolio, delivering benefits in productivity, flexibility and stability to meet growing market needs for shorter label runs and more customization. The AccurioLabel 230 is built on Konica Minolta’s highly acclaimed AccurioPress engine technology, well known for its exceptional print quality and substrate compatibility. The AccurioLabel 230 is targeted at print providers, brand owners, packaging companies and commercial printers looking to bring label production in-house with minimal risk and low initial capital expense. The new model has significant enhancements, including a faster speed (23.4 meters/min), shorter warm-up time between jobs and overprinting capabilities. Last month at Labelexpo, Konica Minolta proudly announced its 450th installation of AccurioLabel engines.

The Precision Packaging Series PKG-675i – Digital inkjet packaging press

The Precision Packaging Series PKG-675i is a corrugated box printer for the customized short run packaging market. Designed for use by folding carton/corrugated box manufacturers and printers, co-packers, packaging marketing and design firms, in-plant printers, manufacturers, commercial and franchise printers, the printer prints on a variety of media including brown craft, white uncoated folding cartons, flats and pre-die cut corrugated media. With fast print speeds and high image quality, the PKG-675i is ideal for everything from box prototypes to short-run lengths for digital on-demand printing and variable data content on cartons and boxes. Its small footprint and user-friendly interface are designed to fit in most environments.

The Precision Packaging Series PKG-675i – Digital inkjet packaging press

The Precision Packaging Series PKG-675i is a corrugated box printer for the customized short run packaging market. Designed for use by folding carton/corrugated box manufacturers and printers, co-packers, packaging marketing and design firms, in-plant printers, manufacturers, commercial and franchise printers, the printer prints on a variety of media including brown craft, white uncoated folding cartons, flats and pre-die cut corrugated media. With fast print speeds and high image quality, the PKG-675i is ideal for everything from box prototypes to short-run lengths for digital on-demand printing and variable data content on cartons and boxes. Its small footprint and user-friendly interface are designed to fit in most environments.

MGI JETvarnish 3D One – Digital print enrichment press

The MGI JETvarnish 3D One digital print embellishment press represents a major new advancement in bringing digital special effects to the mainstream of the commercial printing, finishing and packaging industries. This new press utilizes key components of the 4x PIA InterTech Award winning JETvarnish technology – including the intelligent and adaptive AIS SmartScanner registration system – and is designed for a compact, cost-effective, entry-level solution for all printers.

The small operational footprint of the JETvarnish 3D One allows printers, finishers and converters to have an in-house full production and prototyping print embellishment system without screens, dies or plates. The all-purpose patented varnish formula allows both flat 2D Spot UV highlighting and sculptured 3D raised special effects on a wide range of substrate stocks and media such as paper, synthetics and plastics. Sheet sizes range from 14×29” and the LED 2D/3D effects reach 116 microns in a single pass.

This expansion of MGI’s JETvarnish 3D Series digital print enhancement technology offers a full spectrum of 2D/3D spot coating and dimensional textures for everyone. The cost-effective price point and automatic inkjet head cleaning technology, along with the AIS SmartScanner intelligent registration system, creates a simple, convenient path for developing new digital finishing applications and diverse new application-based revenue streams.

“PRINTING United was the perfect venue for us to introduce such a wide range of revolutionary production and industrial print products,” said Norm Bussolaro, Sr. Director of Marketing, Konica Minolta Business Solutions (Canada) Ltd. “This event brought together attendees from all different sectors of the industry, and from all parts of the world. The number and diversity of those in attendance speaks to our mission to rethink and rejuvenate the print market by bringing new, never-before-seen solutions to the widest number of end-users.”

Source: Company Press Release