The new packaging solution offers the same performance as conventional multi-material packaging while increasing yields for mechanical recycling plants

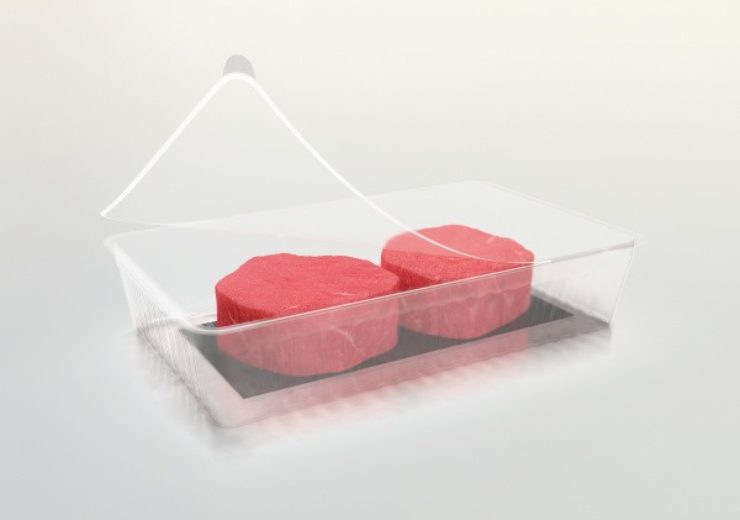

Image: Borealis and Mondi collaboration generates more easily recyclable polypropylene-based food packaging. Photo: Courtesy of Borealis AG.

Packaging and paper group Mondi is using Borealis BC918CF, a BNT-modified copolymer, to produce new monomaterial packaging solutions for meat and dairy products.

Austrian polyethylene and polypropylene manufacturer Borealis has developed an application based on its Borstar Nucleation Technology (BNT) that improves the circularity of plastic food packaging.

The new packaging solution offers the same performance as conventional multi-material packaging while increasing yields for mechanical recycling plants.

Borealis said that the collaboration with Mondi has demonstrated that better material performance can be obtained using the heterophasic copolymer BC918CF along with the random copolymer RB707CF.

The company said that despite being efficient as packaging materials, collected packages of traditional plastic multi-material are usually rejected during the recycling process, reducing yields of mechanical recycling plants and actual materials put back into circulation.

Furthermore, truly viable substitutes for multi-material plastics in food packaging are difficult to find due to complex requirements regarding safety, freshness, hygiene, and visual aesthetics.

Borealis BC918CF and RB707CF are viable monomaterial substitutes

The company claimed that polypropylene (PP) solutions based on Borealis BC918CF and Borealis RB707CF are viable monomaterial substitutes for multi-material plastics as they offer a high moisture barrier, efficient processing on film conversion and packaging lines, and reduce material cost due to downgauging.

Borealis said that the combination of both copolymers in production helps achieve better performance, including thermal resistance and high transparency.

Borealis BC918CF is suitable for downgauging thermoformed packaging as it provides mechanical strength, good moisture barrier, and pleasing optics. In modified atmosphere packaging (MAP), the copolymer provides the required barrier to give the meat a shelf-life of up to 12 days.

As the nucleating effect of BNT is obtained in the polymerisation reactor during the manufacture of PP, it offers several benefits, including a stronger nucleation effect and consistent and better dispersion of the nucleating agent.

Besides, it does not react with other additives, including colour masterbatches, and offers low taste and odour, ensuring compliance with food contact regulations.

Mondi has found that BNT also delivers multiple benefits to converters, including increased stiffness without affecting the drop impact resistance and top load; good thermoforming behaviour and gauge distribution; and high dimensional stability, allowing for high packaging speeds and hermetic seals.