The solution, which has a high level of multiple SKU complexity management and automation, will assist the British business in meeting consumer and retailer expectations of British and Irish food and beverage markets

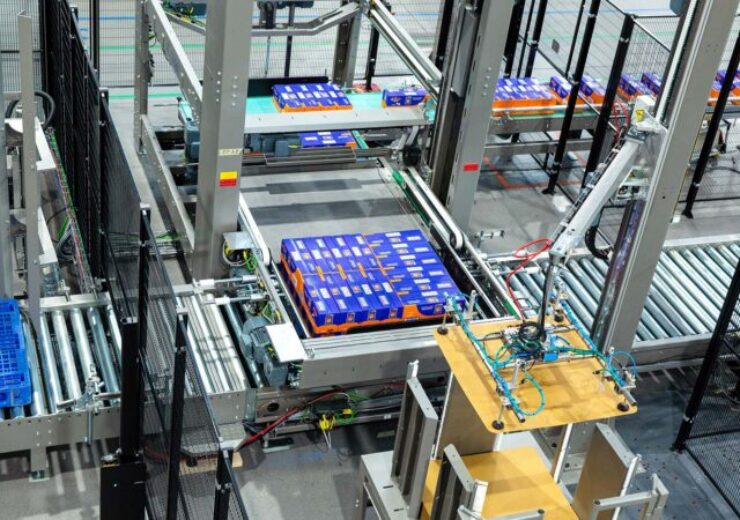

Sidel to install end-of-line turnkey solution for British Sugar. (Credit: Sidel)

French packaging company Sidel has announced a first-time collaboration with sugar producer British Sugar to install a highly flexible end-of-line turnkey solution.

The comprehensive and customised solution will assist the British business, a division of Associated British Foods, in meeting consumer and retailer expectations of British and Irish food and beverage markets.

Both partners will replace British Sugar’s 38-year-old end-of-line system with a new solution that has a high level of multiple SKU complexity management and automation.

According to Sidel, the compact and flexible case packing and palletising solution will be installed in a tight plant area.

The solution is said to have the capability of handling multiple pallet and format types to accommodate single sugar bags to new shelf-ready secondary packaging.

British Sugar Project Integration manager James Warby said: “We needed a partner with strong engineering and design expertise as the challenge was more complex due to the building constraints combined with our high level of technical specifications.”

British Sugar and Sidel identified a single vision for the future end-of-line solution after an extensive period of engagement through conversation and design.

The sugar producer needed a solution with flexibility, dependability, and output speed for case packers and palletisers.

The installation work has already started as part of the initial phase of the partnership between the two businesses.

Sidel’s design and equipment focused on attaining flexibility at a high speed using modern robotics. The French firm will provide a complete turnkey solution, including delivery to the warehouse and sugar bagging outlet.

Sidel account manager Bastien Carcenac said: “To define the right project scope of supply, the British Sugar extended pluridisciplinary team involved in the project always pushed and supported the Sidel team to find the most compact, flexible and efficient solution while ensuring very high standards on all the value chain.”

The end-of-line technology will provide a highly effective solution for future production management, the packaging company added.

The installation is expected to be finished in two further phases towards the end of 2023 and the start of 2024.