US-based MPS has introduced two new next-generation flexo press technologies, the EFS and EFA, to replace the former EF series.

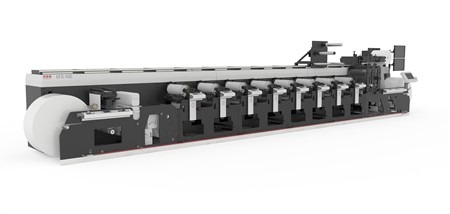

Image: The MPS’ EFS automated multi-substrate press. Photo: courtesy of MPS.

Intended to set new standards in label production and flexible packaging printing, the two automated multi-substrate presses are designed to offer enhanced flexibility, ease of operation and reliability to operators.

The EFS and EFA are designed for printing of labels and flexible packaging on any material, varying from thin unsupported films, self-adhesive labels, shrink sleeves and cartonboard up to 450μm.

MPS Systems CEO Atze Bosma said: “With a beautiful design, new colours and even more operator-friendly innovations, the EFS and EFA flexo presses are the next level that this market demands.”

The well-rounded solution, EFS is designed for label production and flexible packaging printing on various substrates.

MPS said that the EFS press’ ease of operation, high productivity and reliability allows operators to maximize its performance.

The press features the automatic loading of job settings using Job Memory, AutoTeach for quick and automated register settings, and iStop for job changes with minimum waste.

Suitable for the ‘talk to me’ connectivity platform, the EFS is designed with high quality print sleeves, the firm said.

According to MPS, the EFA’s high level of automation, connectivity and ease of operation allows operators to maximize performance.

Additionally, EFA is suitable for technological solutions such as the ‘talk to me’ connectivity platform for data exchange, performance monitoring, pre-loading of job settings and remote support.

Bosma added: “Our EFA is the best option for any printer looking to achieve maximum performance capability from their press.

“With full automation of all print pressure settings and the ergonomic slide-out ink drawer as a standard feature, this press is the ultimate in operator-friendliness. With all options for connectivity, it is the most future-proof solution for a printer’s business.”

The fully automated press, EFA, provides servo-controlled pressure settings for the print sleeves and aniloxes at each print station.

MPS said in statement: “The bold new colour design featured in the EFS and EFA presses will be reflected in production builds of the hybrid EF SYMJET, EXL-Packaging and EXL-Offset presses.”