The lab will speed up the testing of paper and paper-based material to determine how the packaging will act in a large-scale recycling mill

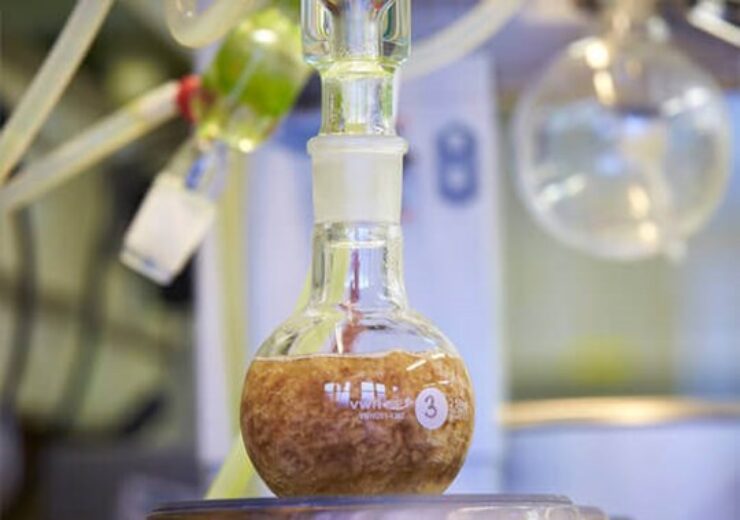

Mondi opens in-house recyclability testing laboratory in Frantschach, Austria. (Credit: Mondi)

Packaging and paper firm Mondi has inaugurated its first recycling laboratory at its Frantschach mill in Austria to test the recyclability of paper and paper-based packaging.

The lab will speed up the testing of paper and paper-based material using non-paper components such as coatings to determine how the packaging will act in a large-scale recycling mill.

According to the firm, internal recycling tests can hasten the creation of environmentally friendly packaging.

Although paper packaging has numerous environmental advantages, it is also limited in its ability to act as a barrier for goods like perishable food.

Mondi said non-paper elements like barrier coatings might need to be added to improve functionality, which could have an effect on how recyclable it is.

The data gathered in the lab can be utilised to enhance current products and offer trustworthy statistics regarding their effects on the environment.

The findings will also be used by Mondi to evaluate how to increase the circularity of material flows and enhance the design of new packaging.

These tests, which are conducted on various paper and paper-based packaging items created by the packaging firm, can show whether the packaging can be recycled effectively.

On a smaller scale, the laboratory operates similarly to industrial recycling plants and the results generated give clear evidence that the material can be recycled.

Mondi R&D and IP Flexible Packaging head Elisabeth Schwaiger said: “The ability to provide our customers with information on the recyclability of our products will be a key enabler in our efforts to develop more sustainable solutions and enhance our value proposition for customers.

“Currently, 78% of Mondi’s group-wide portfolio is already either reusable, recyclable or compostable.

“This recycling lab enables us to move closer to our MAP2030 goals of making 100% of our products fulfil these requirements by 2025.”