The liftaway tray has nine cubes comprises a broad range of sustainably produced fibre-based substrates from virgin and PCW recycled fibre on coated and uncoated surfaces, to Kona and cotton fibre

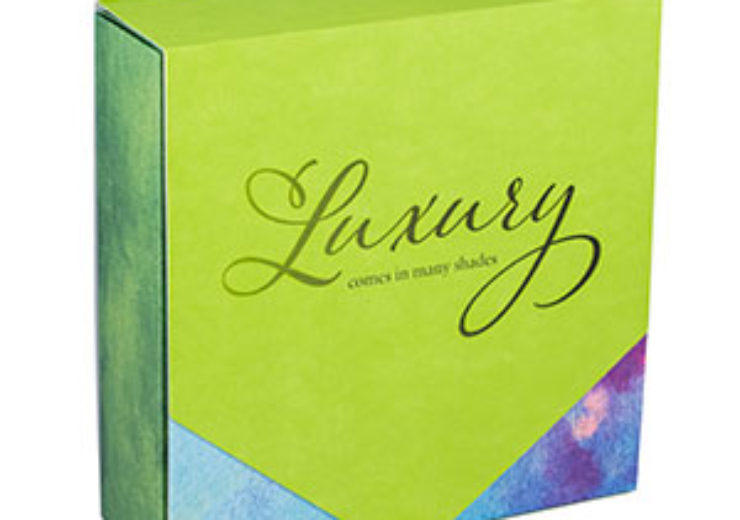

Monadnock partners with Spectrum Packaging to produce retail sample kit. (Credit: Spectrum Packaging Corporation.)

US-based Monadnock Paper Mills has collaborated with a speciality folding-carton package printer Spectrum Packaging to manufacture multi-substrate retail sample kit.

Both companies have partnered to produce a sample kit that includes myriad decorative techniques and paperboard fibre options for luxury brands and retailers.

The sustainable liftaway tray has nine cubes comprises a broad range of sustainably produced fibre-based substrates from virgin and PCW recycled fibre on coated and uncoated surfaces, to Kona and cotton fibre.

The new product packaging, which is designed and crafted by Spectrum Packaging, is claimed to provide unboxing experience to a new level.

The new sample kit can be recycled in curbside mix paper recycle bin

Monadnock Paper Mills sales and marketing vice president Lisa Taylor said: “Spectrum’s attention to detail and commitment to the environment makes them a perfect partner for luxury and lifestyle brands looking to separate their products from the competition.

“The combination of our renewable and recyclable folding boxboard line and their technical and engineering expertise unleashes new packaging possibilities for brand owners.”

The new sample kit has been certified by Forest Stewardship Council, as it ensures the responsible use of forest resources.

It is made of 100% PCW recycled content and is a combination of plant-based fibre options. The new folding box can be recycled in curbside mix paper recycle bin.

Spectrum Packaging sales and marketing vice president Mark Mills said: “This sample will put to rest the lingering misconceptions that high-end brand and retailer packaging with a premium look and feel are incompatible with social responsibility and sustainability.

“Yesterday’s package and paperboard printing technical challenges are today’s premium brand differentiators.”

In 2017, Monadnock Paper Mills has launched its Kona portfolio of packaging substrates made with non-wood fibre from used burlap bags diverted from the landfill.