Flex Films, a film manufacturing unit of Uflex, has introduced two new biaxially-oriented polyethylene terephthalate (BOPET) films.

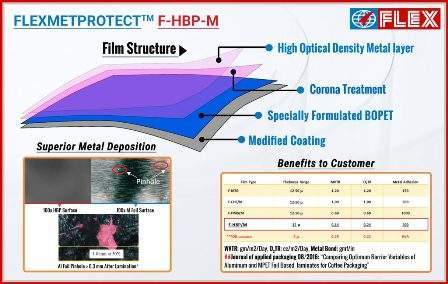

Image: The new Flexmetprotect F-HBP-M BOPET film. Photo: courtesy of Uflex Ltd.

The company has unveiled new Flexmetprotect F-HBP-M and Flexpet F-HPF BOPET films at its manufacturing centre in Kentucky, US.

Flexmetprotect F-HBP-M is a metalized BOPET film with advanced gas barrier, and provides high moisture and oxygen barrier for virtually all applications, including aluminium foil replacement.

High barrier featured has been added with the support of the firm’s patented BOPET film technology, and its high optical density is suitable for most of the flex pack product offerings.

The new BOPET film has been inspected by using the firm’s advanced web metalized surface inspection system.

The film, which is EU and FDA certified, can be used for products requiring foil replacement and extended shelf life with high barrier against oxygen and moisture.

Flexmetprotect F-HBP-M film is suitable for products requiring aroma management such as packaging of coffee and other products such as medicines, snacks, dried meats and nuts.

The film is said to work as an advanced barrier to gases and water vapour with fewer pinholes compared against aluminium foil.

FlexFilms (USA) technology general manager Steven Sargeant said: “With very high optical density, F-HBP-M film has superior tangible advantages. It is one side highly surface modified and other side metalized on corona treatment providing superior gloss, high tensile strength and advanced gas barrier properties.”

Flexpet F-HPF is a biaxially oriented nylon replacement (BON) film, which features newly developed patent pending technology.

Serving as a replacement for BON in multiple applications, the new film delivers better thermoforming performance, as well as provided with high puncture resistance and flexural fatigue strength.

Sargeant further added: “F-HPF is a transparent polyester film having the options of either both sides being untreated or one side being left untreated and other side being corona treated.”

“Due to the enhanced flexibility of the film, it offers pinhole resistance, along with enhanced puncture and crack robustness. These class-leading properties enable this film grade to withstand aggressive handling.”