Mondi aim to further digitalise its business by deploying advanced analytics and automation, to better serve its customers

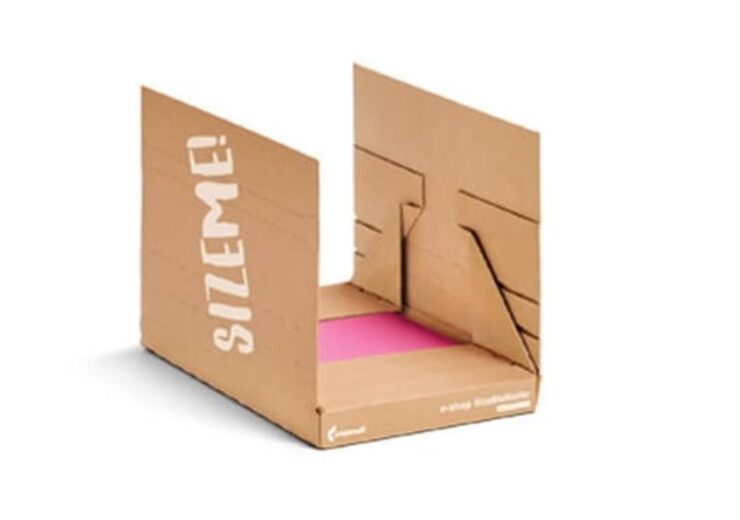

Mondi produces recyclable SizeMeMailer and Envelope Mailer, among others at the Szczecin production plant. (Credit: Mondi)

Packaging and paper firm Mondi has completed the installation of new equipment at its Szczecin corrugated box production plant in Poland to meet the increasing demand for e-commerce packaging solutions in Europe.

The move contributes to Mondi’s aim to further digitalise its business by deploying advanced analytics and automation and provide innovative and sustainable packaging and paper solutions to its customers.

The firm said that the new machinery expands its packaging portfolio while improving production processes.

Mondi Corrugated Solutions COO Armand Schoonbrood said: “This investment in our Szczecin plant has strengthened our e-commerce packaging approach. With our expanded range of sustainable solutions, like our award winning SizeMeMailer and Envelope Mailer, and greater production capacity, our customers will enjoy more packaging options and faster deliveries.

“In parallel, the arrival of these new machines will result in reducing our energy consumption as we focus on limiting our carbon footprint in order to contribute to a better world.”

Mondi installs Masterline 2.1 HD and Robot MUK

In order to meet the increasing demand for e-commerce packaging solutions in north-eastern Germany, Denmark, Sweden and Poland, the firm has installed a five-colour Bobst Masterline 2.1 HD machine as well as a Robot MUK to produce sustainable packaging solutions.

Featuring automatic palletisers, the two machines run at faster speeds to increase production capacity while ensuring high printing quality, Mondi said.

Mondi produces packaging solutions including 100% recyclable SizeMeMailer and Envelope Mailer at the Szczecin production plant.

In a press statement, Mondi said: “Mondi’s expanded range of e-commerce packaging solutions follows the ‘3-e approach’ of being more efficient, economic and easy.

“Not only do they maximise convenience and the customer experience, they can also reduce the costs of logistics and contribute to greater sustainability by reducing product and material waste.”

In July 2020, Mondi has announced plans to expand the capabilities of Aramil and Pereslavl flexible packaging plants in Russia.