Material produced from the Kurtz WAVE FOAMER can achieve 70% recycled content in new applications while offering energy savings of up to 90% compared to traditional reprocessing methods

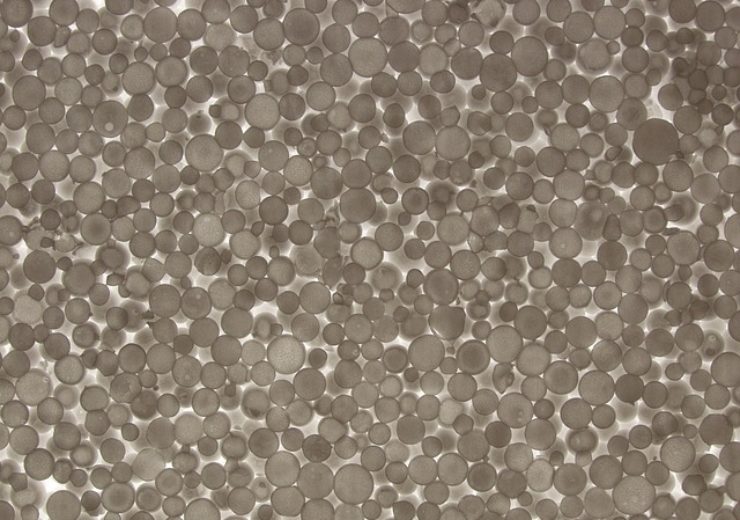

The EPS industry continues to make strides to advance EPS recycling efforts by investing in new technologies. (Credit: LiesbethStemkens from Pixabay)

Expanded polystyrene (EPS) continues to gain attention as news outlets, politicians and environmental groups weigh in with their opinions. However, polystyrene recyclability is either ignored or dismissed as too difficult to recycle, which is negated by the technological innovations and educational outreach highlighted by the Excellence in EPS Recycling Award, now in its seventh year.

To earn the award, nominees – like this year’s winner, Kurtz Ersa – must contribute an outstanding effort to advance EPS recycling. Kurtz GmbH’s winning entry for a new radio-frequency fusion technology, a steam-free foaming method using electrical energy, exemplifies ongoing EPS recycling innovation. Material produced from the Kurtz WAVE FOAMER can achieve 70% recycled content in new applications while offering energy savings of up to 90% compared to traditional reprocessing methods.

“This is a new era of recycling technology,” the judges shared in their comments about Kurtz Ersa. “They have given new life to EPS in a way that mechanical recycling can never do.” The panel of judges this year include recycling industry veterans from Keep America Beautiful, Packaging Digest, Sustainable Materials Management of California and GreenBlue.

Since the inception of the Excellence in EPS Recycling award in 2013, there have been almost 60 nominees that continue to push the boundaries of technology and education. As a result of the EPS industry efforts to work with businesses, universities and municipal waste facilities that want to find creative solutions for difficult to recycle materials, recent data shows that collection rates have bounced back after a regression in 2017 due to the Green Sword. The EPS-IA recycling survey for 62 recyclers in North America confirms almost 43 million pounds (19,474 metric tons) of post-use EPS was recycled in 2018. With new microwave and pyrolysis reprocessing technologies for EPS scaling up, the industry anticipates continuing growth.

Aside from Kurtz Ersa, this year’s nominees also include Atlas Molded Products for their recycling bin blueprints and employee recycling program; the University of Pittsburgh Medical Center, for establishing a model EPS recycling program for medical facilities; and Nutcase, for their bicycle helmet recycling program, allowing consumers to return an old helmet and receive a new EPS helmet for free.

With a global push for action in environmental conservation, awards and other events – such as the 50th anniversary of Earth Day – become much more significant. Policy makers and environmental groups need to embrace innovative environmental solutions to achieve our common goal for increased recycling.

By investing in new technologies, the EPS industry continues to make strides to advance EPS recycling efforts and more importantly, new market applications for recycled EPS. Year after year, the Excellence in EPS Recycling Award demonstrates new and exciting growth opportunities for EPS sustainability.

Source: Company Press Release