Revolution machine is designed to print full-colour graphics on a wide range of cylindrical objects and open-ended tapered vessels

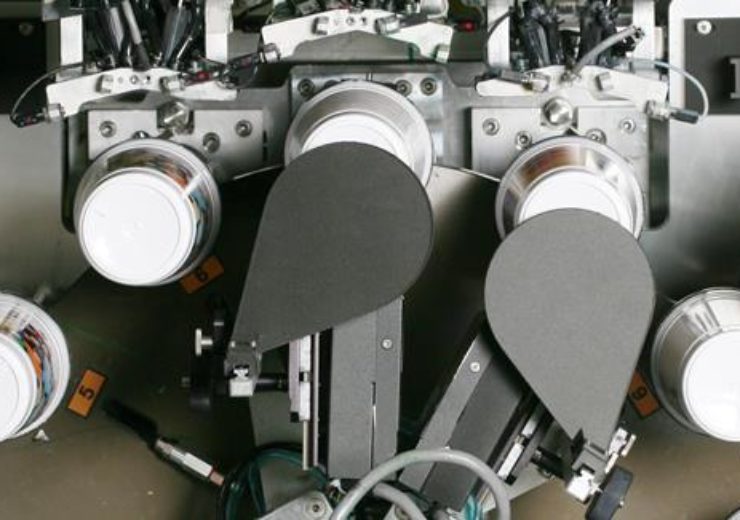

Image: The Revolution features Helical technology to print high resolution graphics on cylindrical items. Photo: courtesy of Inkcups.

US-based printing firm Inkcups has expanded its digital cylinder portfolio with the launch of a new high-speed digital cylinder printer, named Revolution.

The fully-automatic Revolution machine is designed to print full-colour graphics at approximately 600 parts per hour on a wide range of cylindrical objects and open-ended tapered vessels.

The printer features automatic load and unload, integrated pre-treatment and patented Helical printing technology to print high-resolution graphics on cylindrical items.

Revolution’s Helical technology enables printing high-resolution graphics on cylindrical items

The Helical technology is designed to interlace the inkjet drops in a helical pattern while delivering enhanced quality images at twice the resolution and image quality compared to similar machines, Inkcups said.

The firm noted that the Revolution machine can be used for printing on stadium cups, pint glasses, stainless and plastic tumblers, cosmetic jars, glass and plastic bottles, beer cans, oil filters, among others.

Inkcups founder and CEO Ben Adner said: “I feel it is everything we intended to achieve when we started the project over two years ago.

“We set out to develop an industrial printer for the sweet spot in the market – a machine that’s fast enough to produce real volume; flexible enough for quick change over; have the outstanding print quality our customers are accustomed to, and priced competitively.

“The price-to-performance ratio of the Revolution is strong – it is a production machine capable of long runs at one-third the cost of comparable machines on the market.

“We are also proud that our system is designed and built in the U.S. and serviced globally by our experienced team of service engineers.”

The Revolution digital cylinder printer features inline conveyor that enables either manual loading by an operator or automatically load using a robotic system for a more streamlined process.

Inkcups said that the parts are automatically loaded onto 12 vacuum mandrels, deionized, pre-treated with corona or plasma, printed and unloaded onto an exit conveyor following cycling through the machine.

Capable of prints 360-degree seamless graphics with a maximum resolution of 1,200 dpi, the Revolution machine can also print images up to 220mm tall on a part length of 76mm to 305mm, with a diameter of 63.5mm to 111mm.

Currently available in North America, the Inkcups’ Revolution is planned to be rolled out globally in 2020.

In August 2019, Inkcups has launched three new pad printers to produce larger images on longer goods with extended stroke capabilities.