Valmet, a Finland-based supplier of automation technologies, has secured an order to supply a grade conversion rebuild with automation solutions for Shangrao City Lulin Paper in Shangrao, China.

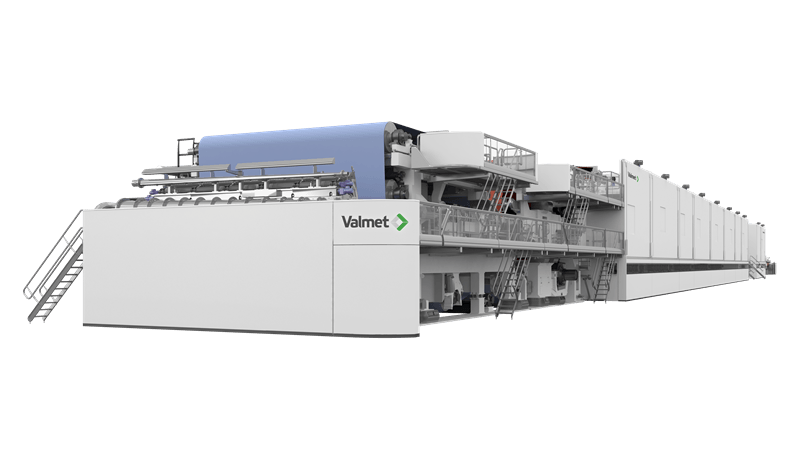

Image: Valmet is supplying technology and automation services for Shangrao City Lulin Paper. Photo: Courtesy of Valmet.

Shangrao City Lulin Paper, which was established in 1990 as a family-owned company, produces liner and core board grades as main products.

Lulin Paper is building a new greenfield mill of 700,000t/y liner and fluting capacity, with an aim to increase the capacity of fluting grades.

The relocated and converted paper machine PM 5 is expected to start functioning at the facility by early 2020.

Valmet says that the present order is included in the orders it received for the first quarter of 2019. Value of the order is not disclosed but typically, for orders of this type, the total value is expected to be around €20m to €30m.

Valmet China capital sales vice president Fan Ze said: “Strong reputation with good references and high-end technology was the key reason for Shangrao City Lulin to choose Valmet. The paper machine, which was originally Valmet-supplied, and its former section with shoe and blade technology set an excellent foundation for a modern and high-speed containerboard machine.”

Valmet’s delivery for the grade conversion rebuild for the start-up includes broke collection, modifications to wet end, new OptiSizer Film with related surface starch preparation system and supply system as well as an OptiReel and a winder upgrade.

Furthermore, Valmet’s service includes board machine ventilation process equipment with a hood, heat recovery with other related air and ventilation systems along with Valmet Paper Machine Clothing package for the start-up.

As part of the automation delivery, Valmet is supplying Valmet DNA Automation System for both process and machine controls, along with runnability and condition monitoring. Final quality of the board is managed with Valmet IQ Quality Control System with a wide- range of profilers and web monitoring system.

The new parts are expected to be working at a design speed of 1,300 m/min and the 8,650-mm wide container board machine is expected to produce fluting grades with a design basis weight range of 60-100 g/m2.