Heathland is focused on recycling post-consumer (PCR) and post-industrial (PIR) plastic waste, including PMMA, PC, ABS, PS, and other thermoplastics

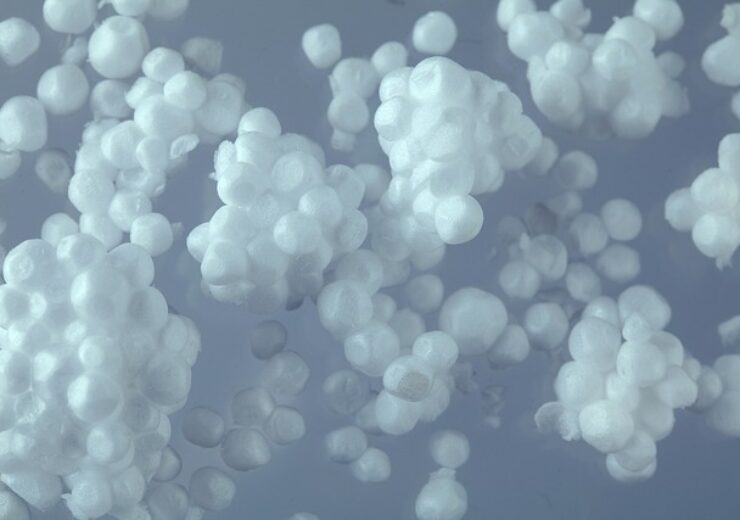

Trinseo closes purchase of Heathland. (Credit: boscoshane from Pixabay.)

US-based materials solutions provider Trinseo has closed the acquisition of Heathland, which is engaged in the collection and recycling of plastic wastes in Europe.

Based in Utrecht, the Netherlands, Heathland is focused on converting post-consumer (PCR) and post-industrial (PIR) plastic waste.

The wastes include polymethyl methacrylate (PMMA), polycarbonate (PC), acrylonitrile butadiene styrene (ABS), polystyrene (PS) and other thermoplastics.

Heathland specialises in collecting, pre-treating and processing plastic waste materials using mechanical and chemical recycling processes.

It transforms the waste into high-quality recycled raw materials for a wide spectrum of applications, to capture the maximum value of the materials.

Heathland’s projects, including its MMAtwo and REVOLUTION, received funding support from the European Commission (EC) under its Horizon 2020 programme.

Trinseo manufactures plastics and latex binders to deliver advanced, sustainable, and value-creating products.

The company has around 3,400 employees working at its 26 manufacturing sites worldwide. It had generated net sales of about $3bn in 2020.

It serves customers in automotive, consumer electronics, appliances, medical devices, packaging, footwear, carpet, paper and board, and building and construction markets.

Trinseo said that the acquisition is in line with its Sustainability Goals for 2030, which focuses on tackling climate change and ensuring sustainability in its product portfolio.

Trinseo SVP and chief sustainability officer Francesca Reverberi said: “Today is another exciting milestone in Trinseo’s transformation journey in becoming a global speciality materials and sustainable solutions provider.

“The addition of Heathland to the Trinseo family enables the group to have access to comprehensive recycling technologies and plastic wastes as feedstock.

“The shared sustainability vision of both companies has now become one. We will continue to invest in the movement toward a circular economy.”

Last month, the US-based firm announced that its STYRON Polystyrene Resins, MAGNUM ABS Resins, and TYRIL SAN Resins now are available with renewable content.

The new sustainable materials are said to combine fossil-based polymers with renewable raw materials under a mass balance process, with 80 to 95% bio-attributed composition.