The new closure liners are said to facilitate up to 100% acceptance into the material recycling stream at municipal recycling facilities

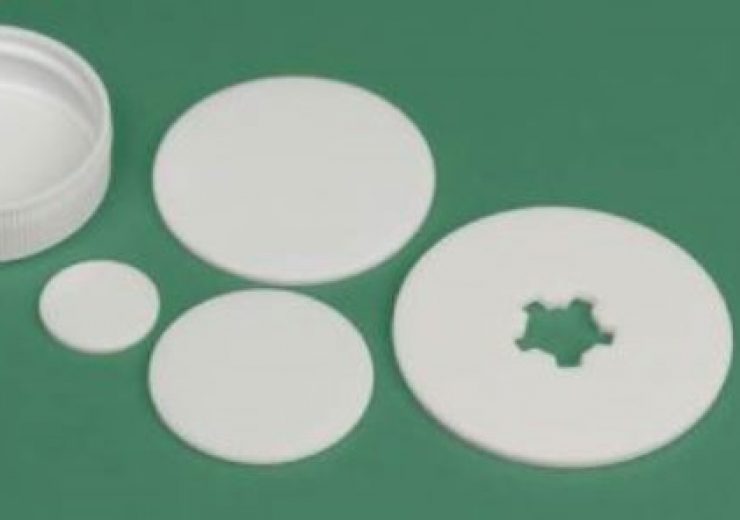

Tri-Seal has introduced new sustainable PP closure liners. (Credit: Tekni-Plex)

Tekni-Plex business unit Tri-Seal has launched a new line of polypropylene (PP) foam closure liners called ProTecSeals for use in different market applications.

The new closure liners are said to facilitate up to 100% acceptance into the material recycling stream at municipal recycling facilities (MRF).

Designed to work in tandem with PP closures, the new PP foam lining will help enhance recycle stream reclamation and result in a recyclable and mono-material solution.

The new material, which is manufactured in both the US and Europe, is suitable for use in different market field applications such as personal care, beauty, home care, agrochemical, nutraceutical, pharmaceutical, food sauces and spreadables.

Tekni-Plex states that the ProTecSeals liners can be identified by a correctly calibrated near-infrared system (NIR) at the MRF as PP. It will help to correctly sort the PP closure and liner into recycle stream #5.

When used with PP closures, ProTecSeals will help customers to meet the EU 2030 target for recyclable plastic packaging without requiring consumers to conduct any material separation before recycling, said Tekni-Plex.

In August last year, Tri-Seal announced that it invested $1m in a new closure liner manufacturing facility in Greater Noida, India.

Tri-Seal is engaged in the manufacturing of a range of closure liners, lidding and healthcare packaging with different materials ranging from a one-piece induction seal to nine-layer extrusions and laminations.

Tekni-Plex is involved in the development and manufacturing of products for different end markets such as medical, pharmaceutical, food, beverage, personal care, household and industrial.

Based in Wayne, Pennsylvania, the company has manufacturing sites across 10 countries globally.