Tetra Pak and milk analysis expert FOSS have introduced an advanced version of the standardisation unit for continuous accurate measurement and control of protein and fat in dairy products.

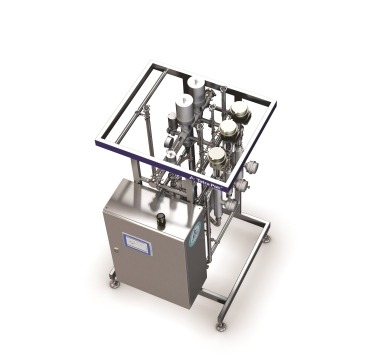

Image: Tetra Pak standardisation unit. Photo: courtesy of Tetra Pak International S.A.

Tetra Pak, a provider of food processing and packaging solutions, said that the new unit will help customers to maintain consistent product quality and increase their profitability by eliminating the uncertainty of sampling techniques.

Both firms have designed fully integrated standardisation process, which uses automation hardware and software algorithms that react and adjust in real time, helping to deliver better ratio performance.

The new solution offers crucial data precisely for every seven seconds, allowing fast reaction to ensure product quality.

The standardisation process is said to provide a range of benefits for customers in cheese and milk powder production, comprising of an advanced performance for fat to protein ratios significantly increasing profit, uniform and on-specification product quality round the clock and elimination of uncertainty associated with manual sampling.

Tetra Pak product manager Helen Sellar said: Integrating our propriety software algorithm and the FOSS analyser in the new Tetra Pak Standardisation units with continuous protein control results in the industry’s most advanced and optimal solution for in-line measurement and control.

“With process variation minimised and profitability boosted, the solution is expected to pay for itself in 2 to 4 years.”

At present, Tetra Pak standardization units with continuous protein control are being evaluated with a Finnish dairy manufacturer Valio.

The new unit is presently marketed in Australia, New Zealand, the US, Canada, Germany, Holland, France, the UK, Denmark, Sweden and Poland, and plans are underway to launch in more markets in 2020.

FOSS product manager Ib Haunstrup said: “A key benefit of the integration of FOSS analytic software within the new Tetra Pak Standardisation units with continuous protein control is the ability to test a number of components directly, eliminating the need for manual testing and enabling producers to run at very narrow margins between specified points.”

Tetra Pak provides packaging equipment for liquid food products, as well as a range of processing and packaging technologies for use with a broad array of products from ice cream and cheese to fruit, vegetables and pet food.