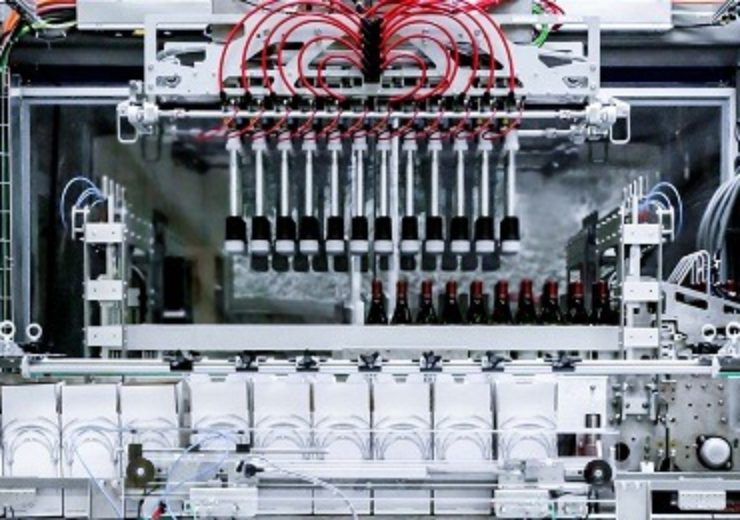

The case packing solution’s auto-adjustable gripping head ensures batch gripping and transfer of 24 to 48 bottles simultaneously

Image: The Sidel’s new Cermex FlexiPack ensures agile packing of wine and spirits bottles. Photo: courtesy of Sidel.

Italy-based packaging equipment manufacturer Sidel has introduced new auto-adjustable Pick & Place case packer, named Cermex FlexiPack, for wine and spirits bottles.

Designed to improve flexibility and overall ease of operations, the Pick & Place case packer is claimed to provide total protection of the primary packaging by enabling 10-minute changeovers while offering enhanced bottle flow management.

Sidel wine and spirits beer global accounts vice president Olivier Goffin said: “Today, both the wine and spirits markets are presenting a very fragmented product offering.

“While this necessarily leads to shorter production runs, it cannot come at the expense of brand equity and product integrity, as both aspects are key components for the attractiveness and differentiation of products.

“Consumers are increasing the pace by which they expect to try new references, new packaging and new tastes with boundaries across drink categories quickly blurring. Brand owners are responding to this development by expanding their portfolio.”

Cermex FlexiPack can handle between 10,000 and 18,000 bottles per hour

Featuring bottle channel infeed, a numerical-axis gantry manipulator and Regular Slotted Container (RSC) case conveying part, the Cermex FlexiPack has the capacity to handle between 10,000 and 18,000 bottles per hour.

Sidel packing product manager Didier Saussereau said: “Cermex FlexiPack handles a wide variety of bottles’ diameters and heights, always paying utmost attention to product integrity.

“Different bottle necks or cap designs do not represent any issue, as the end grippers can be easily and quickly changed.

“All movements are brushless to smooth the product flow at all times as well as allow fully automatic adjustments for changeovers.”

Additionally, the machine is equipped with a single servo-driven auto-adjustable gripping head to ensure batch gripping and transfer of 24 to 48 bottles simultaneously, as well as an upstream DiviArm, a positive bottle distribution system for enhanced product integrity.

Didier added: “For greater accessibility and ease-of-use, the solution comes with the latest version of our user-friendly HMI (Human Machine Interface), helping operators with statistics, diagnostic and maintenance procedures, all available through a tablet-based navigation.”

In July 2019, Sidel has launched X-LITE Still, a new lightweight 500ml PET packaging solution for non-pressurised still water.