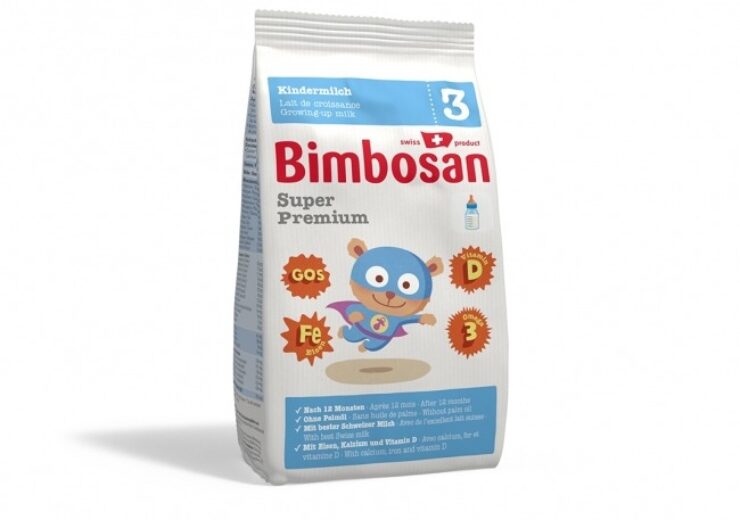

The new sustainable bag is used for Bimbosan’s newest premium baby formula, cereal supplements and cereal paps

The renewable bio-based packaging for Bimbosan’s newest premium baby formula, cereal supplements and cereal paps. (Credit: ProAmpac)

Flexible packaging solutions provider ProAmpac has collaborated with premium speciality baby food products provider Bimbosan to introduce a renewable bio-based packaging for baby nutrition products.

The sustainable bag, which is said to be the first ProActive Renewable product for the baby food market, is used for Bimbosan’s newest premium baby formula, cereal supplements and cereal paps.

ProAmpac’s global flexibles division general manager Adrian Haeberli said: “The ability to create a bag containing renewable material that is designed to meet the unique requirements for an organic baby formula without sacrificing barrier properties or graphics is what makes ProActive Renewable a remarkable innovation.”

More than 65% of bio-resin is used in the sealant layer of the new bag

ProAmpac’s ProActive Renewable solution includes a bio-based resin, which is produced from non-fossil fuel sources.

The flat-bottom form fill sealed bag is comprised of over 65% bio-resin in the sealant layer, while the total package includes more than 40% bio-based material.

According to ProAmpac, the cultivation of bio-resins uses carbon dioxide and released oxygen to deliver bioplastic as a negative carbon footprint.

Bimbosan general manager Daniel Bärlocher said: “Bimbosan has always had the claim to produce special and sustainable products for babies. This is expressed in various aspects of the company philosophy. For example, no palm oil is used in production, local suppliers are considered, and a large number of the products are produced in organic quality.”

In June 2019, ProAmpac announced that it had produced a high-barrier pouch made with 25% post-consumer recycled (PCR) materials for JUSTIN’S new product Nut Butter Covered Nuts.