Proseal's GTSV machine is intended to optimise packaging design while enabling customers to test out novel packaging formats without interfering with ongoing commercial production

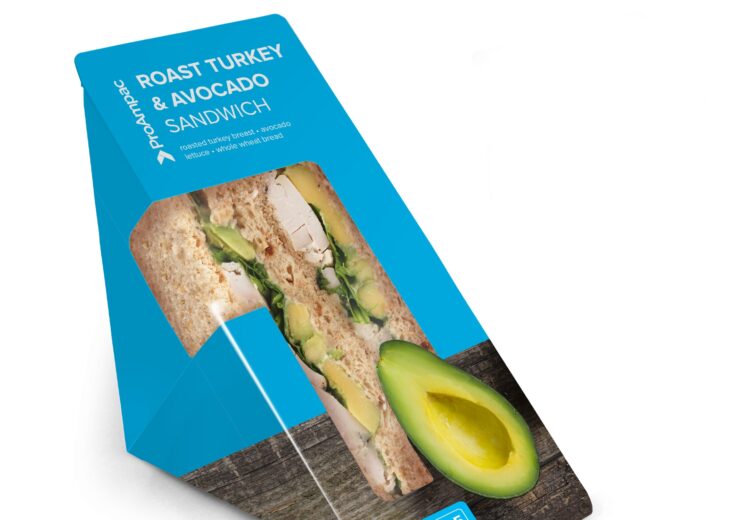

Fibre-based ProAmpac’s Sandwich Wedge. (Credit: Business Wire/ ProAmpac)

Flexible packaging solutions provider ProAmpac and tray sealing machine producer JBT Proseal have partnered to launch North America’s first in-line sandwich packaging testing lab at the former’s Collaboration & Innovation Center (CIC).

ProAmpac said that Proseal’s GTSV machine, which is intended to shape and seal fresh sandwich packaging, will be used to optimise packaging design.

It will also enable customers to test out novel packaging formats without interfering with ongoing commercial production.

With a capacity of up to 50 packs per minute in the Vacuum/Gas cycle, the GTSV is said to be the first modified atmosphere in-line carton sandwich wedge erecting and sealing machine in the world.

The machine also provides atmospheric Seal mode, which can pack up to 70 items per minute and significantly save packaging time compared to rotating alternatives and manual packaging.

The hermetically sealed packaging increases sandwich shelf-life from one week to one month while maintaining product quality, increasing efficiency and lowering the amount of food waste that ends up in landfills.

ProAmpac global fresh food-to-go marketing director Irma Randles said: “The recyclable fibre board sandwich packaging format is in early-stage adoption in North America.

“Having a facility to showcase the packaging functionality on a commercial scale sealing line allows our customers to experience this new technology.

“The fibre format has been an industry mainstay in the UK for years and continues to grow. However, Proseal’s GTSV is the first in-line sandwich high-speed sealing machine in North America.”

ProAmpac’s Sandwich Wedge is a fibre-based package with a thin film coating for product viewing and freshness. It comes in day fresh and modified atmosphere variants for longer shelf stability.

The fibreboard packaging can be recycled in paper recycling streams after the film has been removed, the packaging firm said.

The Sandwich Wedge is lightweight, packaged in a flat-pack configuration for simple distribution and storage, and uses materials made from certified renewable sources.