Rain Barrier’ bags is rain resistant for up to six hours and when stored in damp conditions, can resist water ingress for up to five days

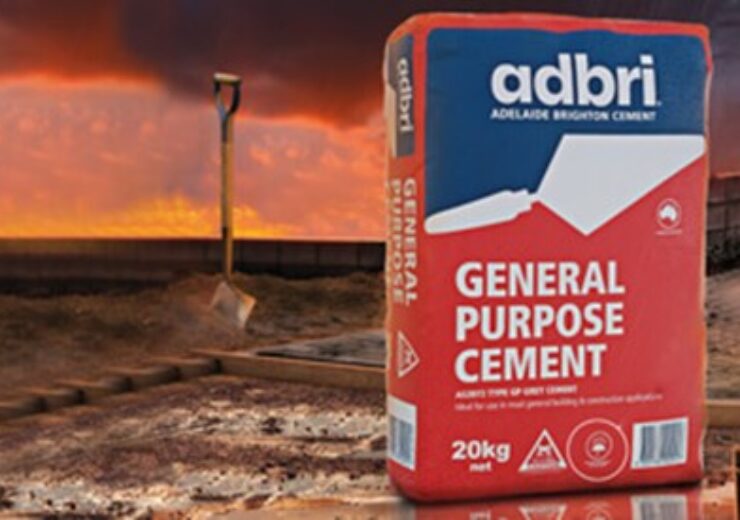

Mondi’s water-resistant paper bags for the Australian cement industry. (Credit: Mondi)

Packaging and paper manufacturer Mondi, together with Adelaide Brighton Cement and Pope Packaging, has launched a new water-resistant paper bag, called ‘Rain Barrier’, in Australia.

Designed for the Australian construction market, the new paper bag is made using Mondi’s Advantage Protect White sack kraft paper.

Featuring water repellent surface, the bag offers high tensile strength in a wet environment and is rain resistant for up to six hours.

When stored in damp conditions, the Rain Barrier bag can resist water ingress for up to five full days.

Mondi Sack Kraft Paper Asia Pacific sales region head Gerry Gosen said: “The new water-resistant paper bags fill just as fast as traditional paper bags and can be filled on existing machinery – so no new investment is needed on the part of the cement companies.

“They are also made from a renewable natural material, which is part of Mondi’s EcoSolutions approach to provide the most sustainable solution for its customers. We’re delighted to have helped make a paper bag solution available in Australia.”

Adelaide Brighton Cement commits to convert paper bags to new water-resistant bags

The new packaging is said to deliver cost savings by reducing damaged product and waste due to moisture ingress.

Pope Packaging papersacks general manager Matthew Sullivan said: “Until the introduction of Advantage Protect and Advantage Protect White in our bag construction, water damage to bagged cement remained a problem on building sites exposed to weather or damp.

“Our Rain Barrier bag offers an unbeatable combination of water resistance in a paper bag, which is less costly and has higher filling speeds than the non-paper alternative.”

Adelaide Brighton Cement, an Australian producer of cement, hydrated lime and packaged products, has committed to convert all of its paper bags used for cement and hydrated lime in South Australia and the Northern Territory, to new water-resistant bags.

The company has been involved in testing and developing of the new water-resistant bags.

Recently, Mondi developed 100% recyclable Coral Tray with lid made of recycled corrugated board for Germany-based BIOhof Kirchweidach.

The new fully corrugated solution replaces BIOhof Kirchweidach’s plastic wrapping for its fresh produce.