The technology, leveraging statistical models and combining several process parameters, predicts the quality values and adjust process parameters in real-time

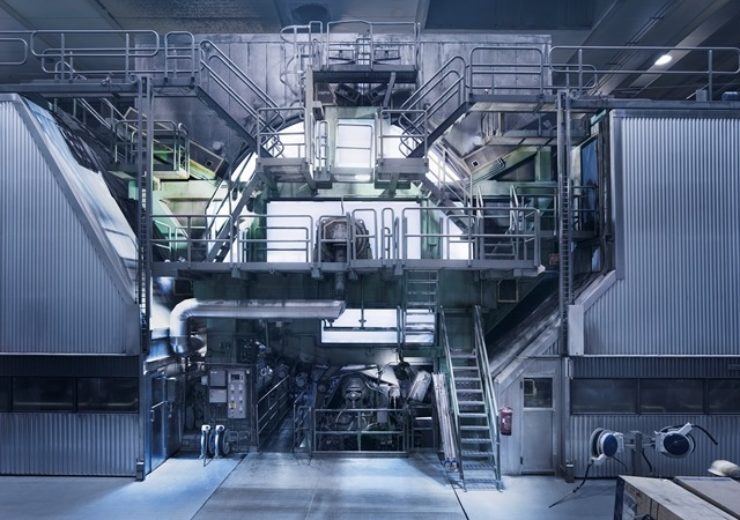

Image: Metsä Board will use AI technology for quality management on folding boxboard machine at Kyro mill. Photo: courtesy of Metsä Group.

Fresh fibre paperboards producer Metsä Board is set to use artificial intelligence (AI) for quality management on the folding boxboard machine at its Kyro mill.

The software, which was provided by Voith, uses measurement results associated with the quality properties of and the mill’s process data.

Deployment of artificial intelligence at Kyro mill

With the support of various process parameters and statistical models, the system can automatically predict quality values and adjust process parameters in real-time.

The process will help enhance the production efficiency of the folding boxboard machine, in addition to improving quality consistency.

The company is also evaluating possibilities for the deployment of AI technology at its other mills for the improvement of the performance.

Metsä Board development SVP Ari Kiviranta said: “Artificial intelligence will contribute to high efficiency and accuracy of production process control. Production waste will decrease, product quality consistency will further improve and grade changes will be quicker.

“The operators at the mill can now focus on comprehensive management and operational development.”

Earlier this month, Metsä Board has participated in paperboard cup collection initiative in France. Metsä Board is one of the founding members of Alliance Gobelet Carton, which was created in the spring to conduct a pilot for the collection and recycling of paperboard cups in France.

The alliance is planning to create a collection system for the recycling of paperboard cups. It aims to bring together cup producers, paperboard suppliers, cup users and the recycling sector.

In June this year, Metsä Board announced that it will build a paperboard and packaging excellence centre in Äänekoski, Finland.

The new centre will combine packaging design and R&D excellence under one roof to help develop new paperboard and packaging solutions for the future. It will be located in a bio-economy ecosystem that is unique in the world, said the company.