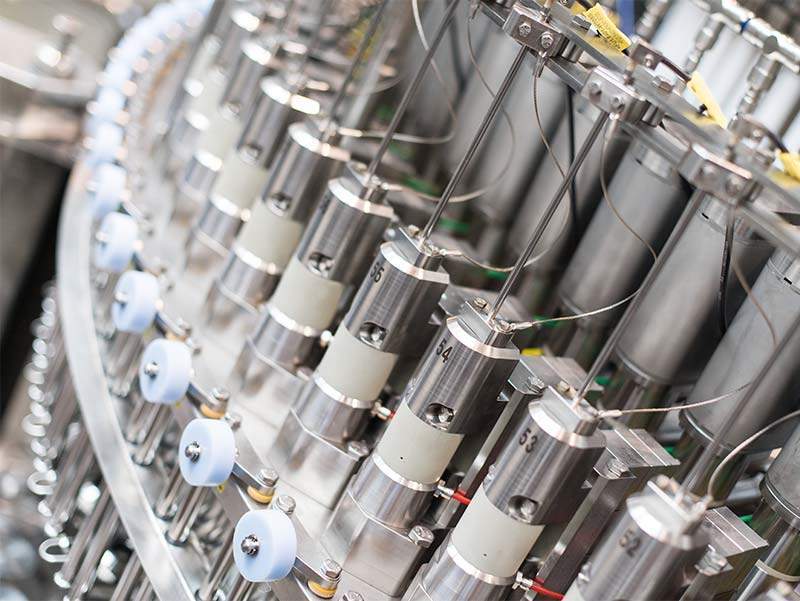

German packaging and bottling company Krones has modified its beer bottle filling machinery, Modulfill HES, after considering various technical and hygienic aspects.

Image: Krones redefines Modulfill HES bottling machinery. Photo: Courtesy of Krones AG.

Krones stated that the changes have been made from the bottle infeed, plus filling and closing, right through to bottle discharge.

Several new features and design enhancements have been made to ensure that the filling system offers various specifics in terms of safety, operator-friendliness, space saving and hygiene, the bottling company stated.

Modulfill HES features latest generation of PFR valves, which have ability to steplessly adjust the flow velocity, enabling the customer to match the filling function with the product characteristics involved. The usual fobbing encountered with beer can now be eliminated.

The upgraded beer filling machine has stepless probe adjustment capability, which enables an easier and shorter change of the containers. With linear actuators, the probe can be adjusted to an accuracy of one-tenth.

If a glass container breaks during filling, sensors will detect immediately and trigger a gush-type-jetting function. The splinter washout system will feature a self-draining base frame and table in hygienic design. The upgrade has more components in the direct vicinity of the filling function.

The rollers will in future be in dry-running design and will no longer require water for lubrication.

Furthermore, the upgraded Modulfill HES includes a lifting-rod assembly’s cam will feature a serrated drip edge, which helps in the selective removal of the water dripping off.

As part of the upgrade project, Krones has also revamped the connected closing and sorting systems for crowns and aluminum roll-on closures. For the crowner, speed can now be increased by 20%.

The company said that the lubrication has been minimised by means of lifetime-lubricated running rollers and an automatic single-point lubrication system for the cams.

Krones is a manufacturer of lines for filling beverages in plastic and glass bottles or beverage cans.

The firm produces stretch blow-molding machines for producing polyethylene terephthalate (PET) bottles, plus fillers, labellers, bottle washers, pasteurisers, inspectors, packers and palletisers.