Both Hop-Syn’s 8 and 10 mil waterproof and durable synthetic substrates have been added to Konica Minolta’s Approved Media Guide

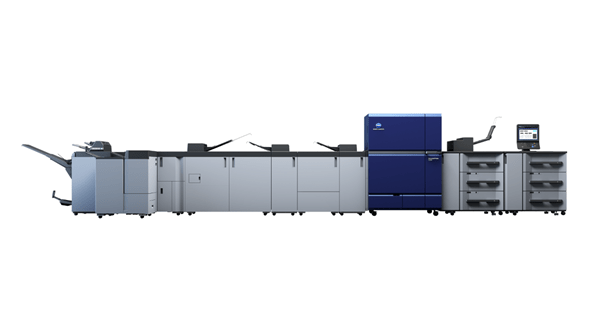

Konica Minolta approves Hop-Syn XT Synthetic Papers for AccurioPress machines. (Credit: Konica Minolta Business Solutions U.S.A., Inc.)

Konica Minolta Business Solutions, a in industrial and commercial printing and packaging solutions, today announced the testing and approval of Hop-Syn XT Synthetic Papers for use on its AccurioPress C14000/C12000 digital presses. Both Hop-Syn’s 8 and 10 mil waterproof and durable synthetic substrates have been added to Konica Minolta’s Approved Media Guide.

“Hop-Syn’s XT substrate is the first synthetic paper to be approved for the AccurioPress C14000, the result of rigorous testing in our Japanese facilities,” said Dino Pagliarello, Senior Vice President, Product Management and Planning, Konica Minolta. “Our customers make huge investments with us in purchasing our presses, and deserve the utmost assurances that our partners’ products will perform as expected for their specific applications.”

Hop-Syn XT is an extra tear-resistant synthetic paper made from a unique mixture of calcium carbonate and polypropylene resin. The XT grade paper is manufactured with UV inhibitors and additional whitening agents to improve its sheet brightness and opacity up to 94%. With a high dyne level and smooth matte finish, Hop-Syn XT has the printing performance expected from a fine offset paper, but with the extra tear strength and weather resistant properties that allow print promotions to meet the most demanding environmental conditions.

Hop-Syn XT is available in a variety of roll widths, sheet sizes and gauges, with a thickness range of 4mil up to 10mil, roll widths of 55” and 61” and sheet sizes 25”x 38” and 26”x 40″. Popular applications include POP displays, signs and banners, hang tags, shelf talkers, book covers and outdoor product guides. Hop-Syn XT is also perfect for businesses requiring waterproof materials that can be cleaned with disinfecting spray or wipes, such as menus in restaurants.

“Knowing our products qualified for these new machines now hitting the market after extensive testing at Konica Minolta’s headquarters in Japan will provide owners with confidence in both reproduction quality and printability of our tear resistant and waterproof Hop-Syn Synthetic Papers.” said John Risdon, Account Executive, Hop Industries. “Seeing our XT material printed at the introduction of the C14000 and C12000 at Printing United, and during subsequent demos at Konica Minolta’s new Customer Experience Center in Ramsey, New Jersey was an exciting opportunity and also a great learning experience.”

Konica Minolta’s Formalized Substrate Testing Process and Media Guide

Several factors, including increasingly higher production speeds, have necessitated closer inspection of substrates to assess their suitability for Konica Minolta AccurioPress digital presses. Papers must be well manufactured, run consistently and generally meet the demands of the press from pick-up and registration through to toner transfer, fusing and exiting the press for post-processing steps. Konica Minolta’s approval process includes testing on feed, fusing, jamming, registration, slipping, curling and scratching. Approved substrates are added to the new Media Guide, created for commercial printers as a trusted resource for a wide variety of substrates.

Source: Company Press Release