Process control and yield management solutions provider KLA-Tencor has expanded its integrated circuit (IC) packaging portfolio with two new inspection systems.

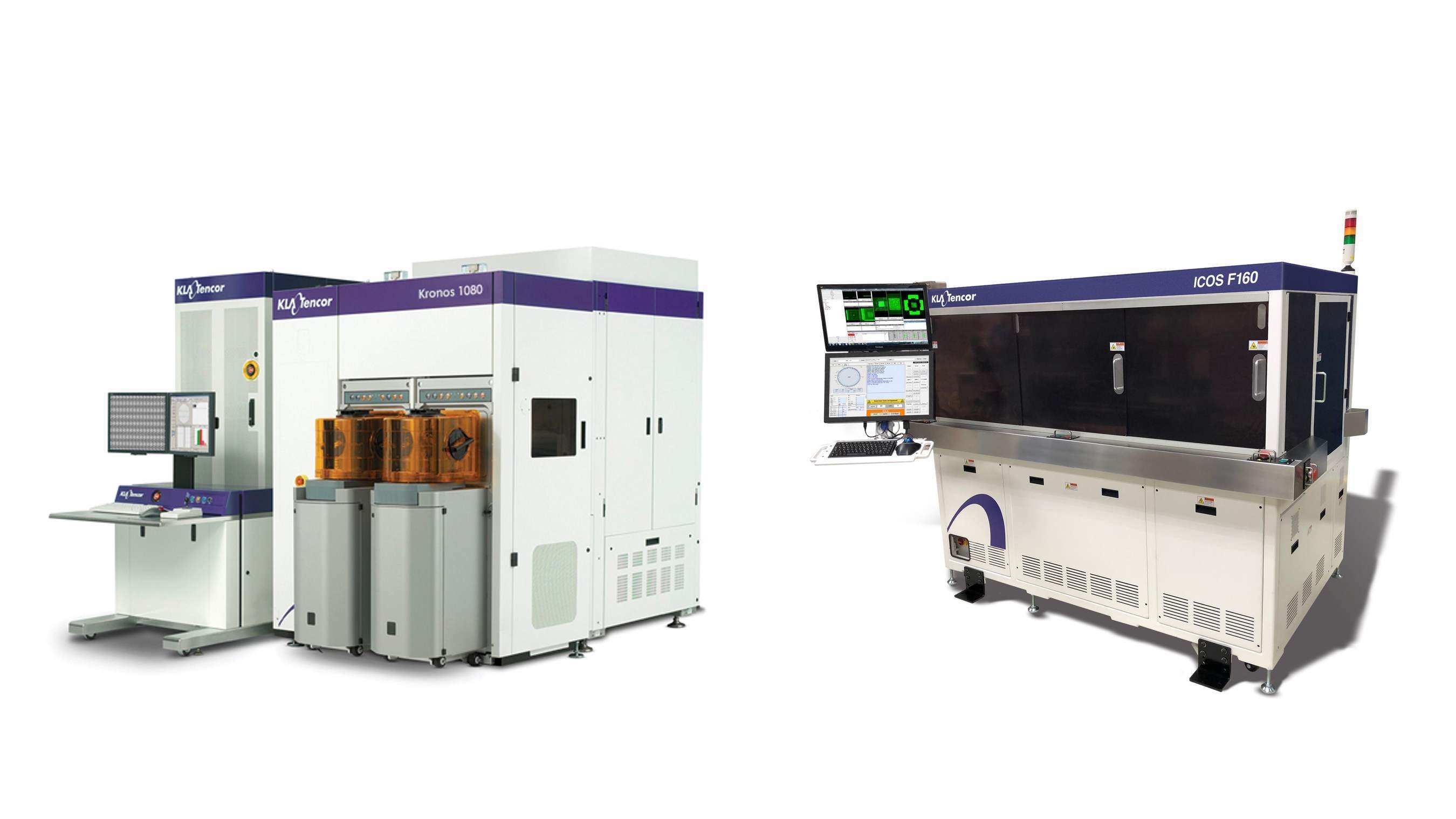

Image: KLA-Tencor’s new Kronos™ 1080 wafer inspection system and ICOS™ F160 die sorting and inspection system are designed to address a wide variety of IC packaging challenges. Photo: courtesy of KLA-Tencor Corporation/ PRNewswire.

The Kronos 1080 and ICOS F160 defect inspection systems are designed to address several IC packaging challenges.

The Kronos 1080 system offers information on the entire range of defect types for inline process control by inspecting advanced wafer-level packaging process steps.

KLA-Tencor said the Kronos system achieves its performance via multi-mode optics and sensors and advanced defect detection algorithms.

The system also introduces FlexPoint, an advanced technology derived from KLA-Tencor’s inspection solutions for IC chip manufacturing.

The FlexPoint technology focuses the inspection system on important areas within the die where defects would have highest impact.

Flexible wafer handling enables to inspect high-warp wafers, frequently encountered in a package type dubbed fan-out wafer-level packaging, the company said.

The ICOS F160 undertakes inspection and die sorting following the testing and dicing of wafer-level packages.

KLA-Tencor noted that high-end packages manufacturers, such as those used for mobile applications, will benefit from new capability to identify laser-groove, hairline and sidewall cracks.

The cracks arise from a change in the materials utilized to insulate the dense on-chip metal routing to support increased speed and decreased power consumption.

The ICOS F160 system’s input and output modes can be wafer, tray or tape. The system can be changed from one configuration to another.

The automatic calibrations and precision die pickup of the system results in increased tool utilization in high volume manufacturing environments.

Last month, KLA-Tencor has announced Voyager 1015 and Surfscan SP7 defect inspection systems: to address two key challenges in process and tool monitoring.

US-based KLA-Tencor, partners with customers around the world to develop inspection and metrology technologies.

Headquartered in Milpitas, California, the company has dedicated customer operations and service centers across the world.

KLA-Tencor’s portfolio of packaging solutions includes the CIRCL -AP all-surface wafer inspection system, Zeta-580/680 3D metrology system for wafers and panels, ICOS T890, T3 and T7 Series component inspection and metrology systems, and Klarity data analytics system.