The addition of the new press will boost JohnsByrne's comprehensive in-house printing and finishing technologies.

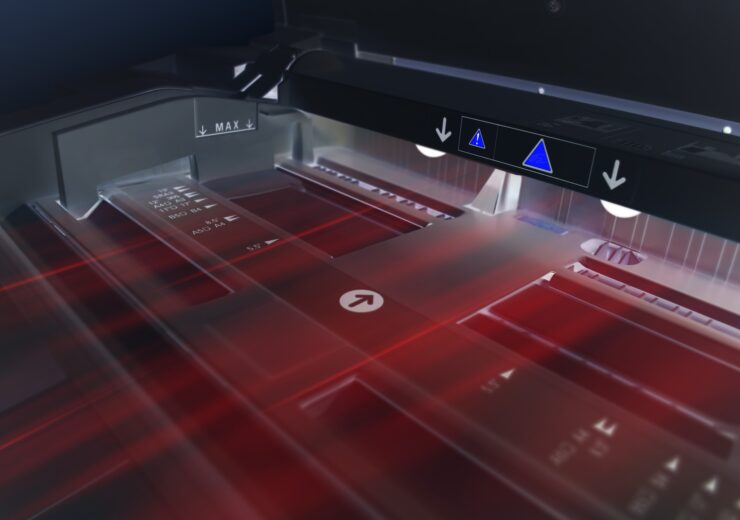

The press is the latest in sustainability and AI to deliver speed-to-market. (Credit: Crea Park from Pixabay)

Premium packaging and high-impact direct mail supplier JohnsByrne Company has announced the acquisition and installation of a new Heidelberg Speedmaster XL eight-colour press.

The carbon dioxide-neutral press represents the company’s latest capital expenditure in sustainability and AI to deliver speed-to-market environmentally friendly packaging.

According to the firm, the new press is the most energy-efficient, highly automated press currently available, that uses both AI and big data.

It enhances the internal printing and finishing technology of JohnsByrne and is procured to address sustainability and speed-to-market issues.

Heidelberg uses a method to calculate the overall greenhouse gas emissions in order to offset the environmental cost of building it, as part of sustainability commitment.

The new press also runs faster and can save energy while in operation.

The addition of the Heidelberg press will help JohnsBryne to offer structural design for less packaging waste. It will also facilitate the use of sustainable materials, including environmentally friendly ink and embellishments.

Additionally, JohnsBryne will help its customers to meet sustainable packaging goals through the use of VOC-free alternatives.

JohnsByrne president Corey Gustafson said: “We are committed to investing in people and technology to drive our success as well as the success of our customers.

“We continue to add equipment that brings what we promise customers – speed-to-market, excellent quality and innovation.

“When looking for the right equipment to add to our press room, we extensively search out the latest technology and are excited about the newest printing and packaging capabilities.”

JohnsByrne focuses on making folding cartons, specialty packaging, point-of-sale, and high-impact direct mail solutions. During the Covid-19 pandemic, it also designed protective face shields for essential workers and first responders.