Schreiner ProTech’s attaches a paint mask to the marking label to protect the inscriptions of marked components during the painting process

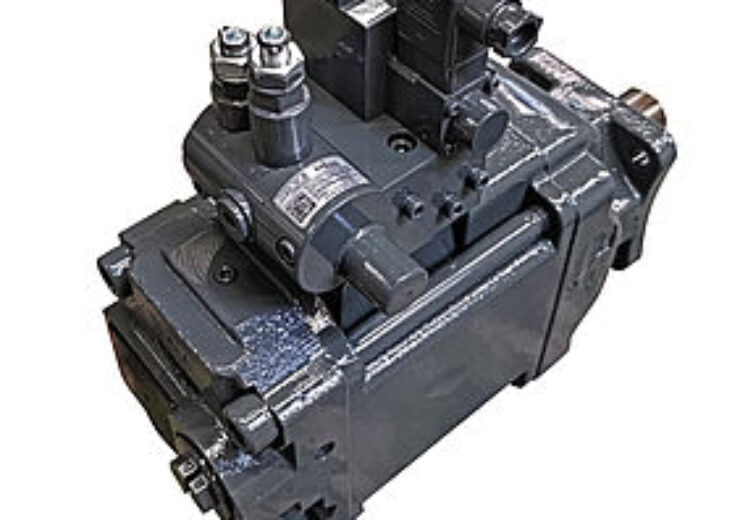

InLine Hydraulik’s Hydraulic pump with folding paint mask after painting process. (Credit: Schreiner Group)

German industrial engineering company InLine Hydraulik has selected Schreiner ProTech’s new label with a paint mask designed to safeguard component marking legibility.

The new solution will be used by InLine Hydraulik to preserve the readability of markings applied to regulators and hydraulic pumps.

Schreiner ProTech said its solution attaches a paint mask to the marking label to protect the inscriptions of marked components during painting.

The masking effect is initiated by a folding mechanism following the inscription of a standard 2D identification code.

In a press statement, Schreiner said: “Schreiner ProTech’s paint mask solution offers the additional option of combining a removable paint mask label with durable overlaminate that permanently protects underlying nameplates against mechanical stress.”

The protective label on the component is peeled off using starter tab

The protective label on the component is peeled off using a starter tab following the paint drying process.

Since the paint mask is significantly smaller than the marking label, the label remains embedded in the paint upon the removal of the paint mask film for permanent marking protection.

InLine Hydraulik earlier utilised metal nameplates to mark components at the end of the production process.

The work, however, provided limitation that excluded the automated integration of digital information for storage or traceability.

Schreiner noted that the new folding paint mask labels are imprinted with 2D codes on-site followed by manual application to pumps and regulators early in the production process.

The paint mask is peeled off while preserving the code’s readability reliably preserved, thus optimising the manufacturing process while allowing for automated traceability.

The new RFID label has been designed to meet the RFID systems poor performance issues on ESD containers while enabling end-to-end batch tracing on the container level.