Harpak-ULMA will implement intelligent, networked packaging platforms with highly automated product loading and secondary/tertiary pack-out activities in the collaboration project

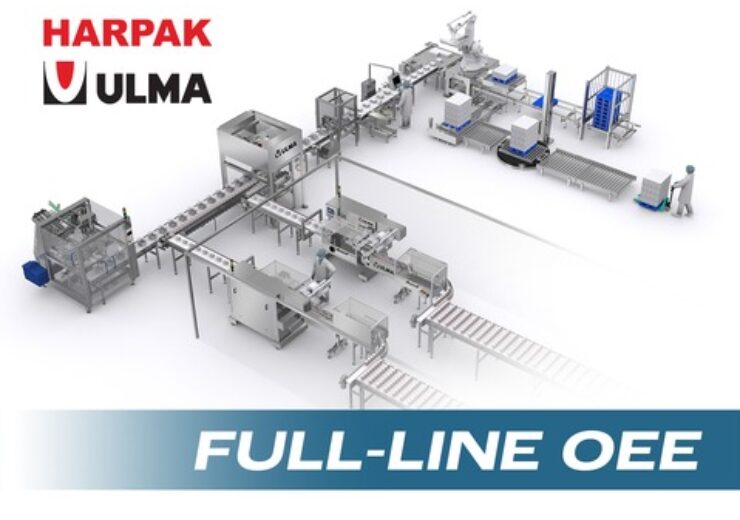

Harpak-ULMA end-to-end packaging solutions feature product loading, primary, secondary, and tertiary packaging capabilities. (Credit: Business Wire/ Harpak-ULMA)

Packaging machinery maker Harpak-ULMA has been selected by a medical device manufacturer to supply automated flow wrap packaging lines for pipette tip production.

With the move, a device used to dispense precise liquid volumes in disease research and diagnostic labs will be produced reliably in the US.

Harpak-ULMA will implement intelligent, networked packaging platforms with highly automated product loading and secondary/tertiary pack-out activities in the collaboration project.

The high standards of scalability, medical device packing quality, and overall throughput required at high production levels will be met or exceeded by the company’s solutions.

The selection was based on the capacity of Harpak-ULMA to provide an end-to-end, integrated solution, from upstream product handling and tracking through primary and secondary packaging to integrated pack-out stations.

This total line solution will enable a centralised control system to optimise equipment communications by tracking Line OEE in addition to individual equipment OEE.

The multi-year, multi-phase strategic plan of Harpak-ULMA covers real-time digital twins, augmented reality (AR) training experiences, remote OEE monitoring, analytics deployment, and machine self-diagnosis.

The mean-time-to-repair (MTTR) can be decreased by giving front-line workers access to tools like AR experiences that can accurately direct staff through difficult fixes that may have previously required OEM field support.

Predictive maintenance capabilities are also made possible by smart, linked platforms, opening up the possibility of virtually eliminating unscheduled line downtime.

An additional strategic justification for this government measure is provided by Harpak-digital ULMA’s transformation strategy, which focuses on creating and implementing information-centric, next-generation packaging solutions.

Furthermore, the end-to-end automation expertise and capabilities of the firm will provide a lone point of accountability to ensure the system commissioning is completed on schedule and within budget.

Harpak-ULMA Medical Industry product manager Nick Kirichkow said: “Our smart, connected packaging platforms enable innovative technologies to achieve these outcomes – all while maximising line output, scalability, and flexibility.”