MRSjump Extruder can process post-consumer PET regrind from thermoformed trays directly to sheet for thermoforming trays

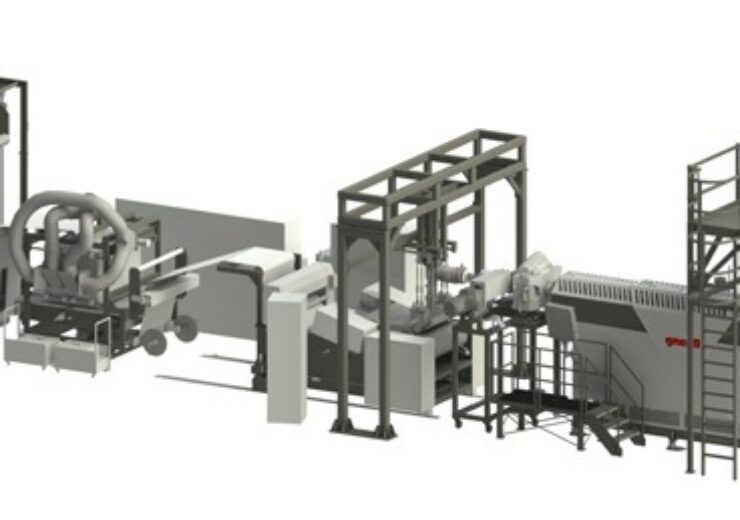

The MRSjump Extruder is designed for processing of tray-to-tray recycling. (Credit: Gneuss Kunststofftechnik GmbH)

Gneuss, a provider of innovative solutions to the plastics processing industry, has developed new MRSjump Extruder for the process of tray-to-tray recycling.

The new MRSjump Extruder has been designed to process post-consumer PET regrind from thermoformed trays directly to sheet for thermoforming trays while meeting the requirements of completely circular modern food packaging.

The machine combines the high decontamination performance of the MRS degassing extruder with a viscosity boost.

MRSjump extrusion process eliminates pre- or post-treatment of input material

Gneuss said that the MRSjump extrusion process eliminates the need for pre- or post-treatment of the input material, such as crystallisation or pre-drying of the recycled material or an IV boost in a solid state polycondensation (SSP).

Additionally, the MRSjump Extruder’s high degassing efficiency allows it to comply with the European Food Safety Authority (EFSA) and US Food and Drug Administration (FDA) limits without time- and cost-intensive upstream or downstream material treatment.

Featuring a compact design, the MRSjump Extrusion System can easily be retrofitted to an existing sheet line within the same spare requirements as an existing conventional extruder.

The MRSjump Extruder is capable of processing a wide range of input materials regrind from mono- and multi-layer trays to material combinations while avoiding upstream or downstream material treatment steps.

In a press statement, Gneuss said: “The simple set-up of the MRSjump direct extrusion process avoids the combination of different material treatments prior or subsequent to extrusion and resulting interface problems.

“Thanks to the short process chain, the melt remains within a narrow, defined residence time spectrum. The thermal and mechanical stress on the material is kept low. This results in excellent mechanical and optical sheet properties.”