New facility featuring next-generation technology expands FlexXray's ability to provide dependable inspection and QA hold resolution services with shorter shipping times and reduced freight charges to the Northeast region

The new facility will provide the fastest, safest and most accurate foreign material inspection and QA hold resolution services to food and product manufacturers. (Credit: FlexXray)

FlexXray announces the opening of a temperature-controlled, USDA and FDA-registered inspection facility specializing in foreign material QA Hold resolution services located at Americold Logistics (2111 Industrial Way, Vineland, NJ 08360). This expansion is in response to the demand for FlexXray’s industry-leading services in the Northeast region rapidly increasing among the vital food and beverage production facilities in this area of the country.

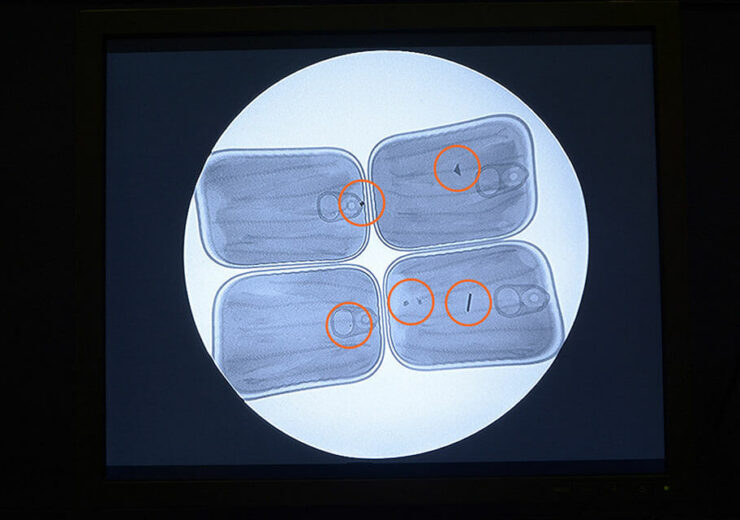

The new facility will provide the fastest, safest and most accurate foreign material inspection and QA hold resolution services to food and product manufacturers across the Northeastern United States. It will feature multiple inspection lines using FlexXray’s new proprietary next-generation advanced digital technology that can detect contaminants, including plastic and metal as small as 0.2mm in size. This new facility will have an initial capacity to process up to four truckloads of product per day. In addition to FlexXray’s well-known X-ray inspection services, it will also soon offer additional value-added services, including cold storage, contaminant retrieval, manual sorting/packaging, and metal detection.

“We’ve seen a significant increase in demand for our services in the Northeast due to the strong immediate return on investment associated with product remaining in commerce. Not to mention the overall waste elimination our customers experience thanks to our services. We’re opening this new plant to be closer to our customers so they can take full advantage of our next-generation technology which may detect contaminants, including plastic, that can’t be detected by other systems. We are delighted to take this next step in our long-term vision to serve food producers throughout the United States with fast and effective state-of-the-art solutions via conveniently located regional service centers,” said FlexXray CCO, Kurt Westmoreland.

At full capacity, this new facility will run 24 hours per day with multiple shifts and will inspect over eight truckloads of product every day. The facility will feature the ability to inspect multiple trucks at the same time, including the ability to inspect an entire truck in as little as three hours – while the driver waits.

FlexXray looks forward to advancing its commitments to product safety and waste reduction in the food and beverage industry while continuing to serve customers with the best quality and customer service in the industry.

Source: Company Press Release