Germany-based Coperion has introduced a completely flexible continuous pharma extrusion system for wet and hot melt extrusion processes.

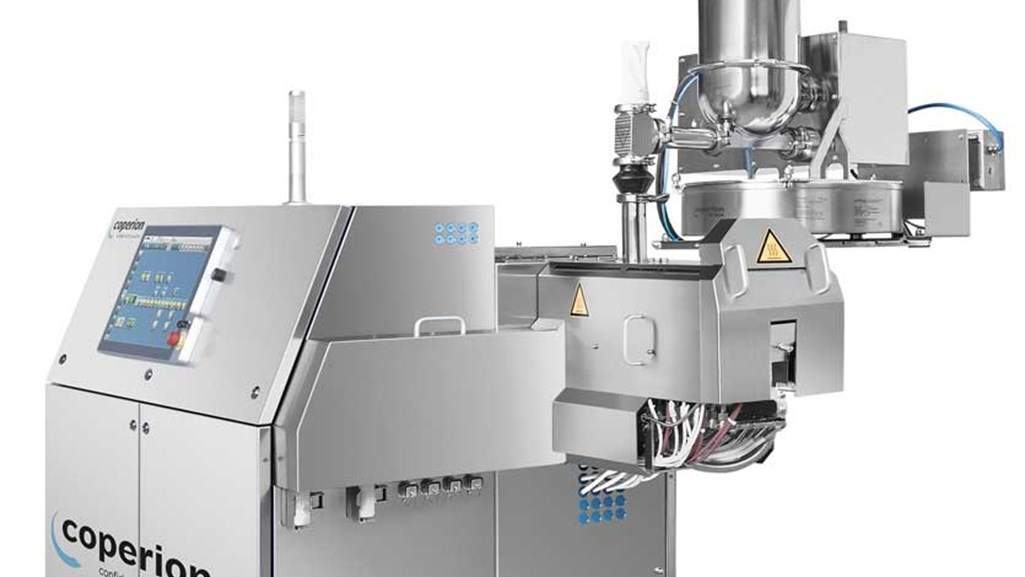

Image: Coperion’s ZSK 18 MEGAlab twin screw extruder. Photo: courtesy of Coperion GmbH.

Coperion said its ZSK 18 MEGAlab extruder is suitable for research and development, as well as for small-scale production. It offers maximum throughput rate of 10 kg/h.

The ZSK 18 MEGAlab extrusion system with 18mm screw diameter has been delivered to an international pharmaceutical firm, which is being used for different continuous process tasks.

The twin screw extruder features two Coperion K-Tron gravimetric loss-in-weight feeders with enhanced accuracy in API and liquid feeding, as well as cooling belt and Coperion pelletizing technology strand pelletizer.

The new system has been provided with more than ten different die plates with various numbers of die holes and die hole diameters for use in wet extrusion processes.

For hot melt extrusion applications, the company has installed the equipped the ZSK extruder with a die head that has several exchangeable nozzles to offer different strand diameters.

The die head provides additional bore holes for process analytical technology (PAT) sensors.

Coperion K-Tron liquid gravimetric loss-in-weight feeder, which meets ATEX requirements, can be linked to each of the barrels of the extruder process section. This flexibility in feeding can also be applied to the Coperion K-Tron API gravimetric loss-in-weight feeder.

The extruder can be mounted on the first barrel or fourth barrel of the process section, enabling it to use for processes requiring process lengths of 32 L/D as well as of 20 L/D.

Coperion K-Tron gravimetric feeders can deal with a wide variety of materials, including products with difficult flow characteristics and variable feed rates.

This flexibility, along with Coperion K-Tron’s superior digital weighing and controls technology, allows to maintain accuracy in materials feeding, which is crucial to the continuous pharmaceutical process.

Coperion food and pharma business unit general manager Stefan Gebhardt said: “We have designed an extrusion system that optimally meets two very important requirements of the pharma industry. The system offers a large number of features for various application processes and at the same time fulfills all state-of-the-art GMP requirements.

“This way the ZSK extrusion system can be used with maximum flexibility – for a wide range of research and development tasks as well as for clinical trials and small-scale production processes.”