With major companies and governments trying to curb the plastics problem, does Finland's sustainable materials developer Paptic have the answer?

(Credit: Paptic)

Finland-based sustainable materials developer Paptic claims to have found the answer to help combat one of the biggest threats to our planets ecosystem – plastic bags.

It’s estimated that in the US alone, 100 billion plastic bags are used a year, requiring 12 million barrels of oil to manufacture and more than 500 years to degrade in landfill.

Businesses and governments have taken an array of measures to help to counteract the problem – with three US states banning single-use plastic and British supermarket chain Morrisons set to begin selling paper bags in its stores in May 2019.

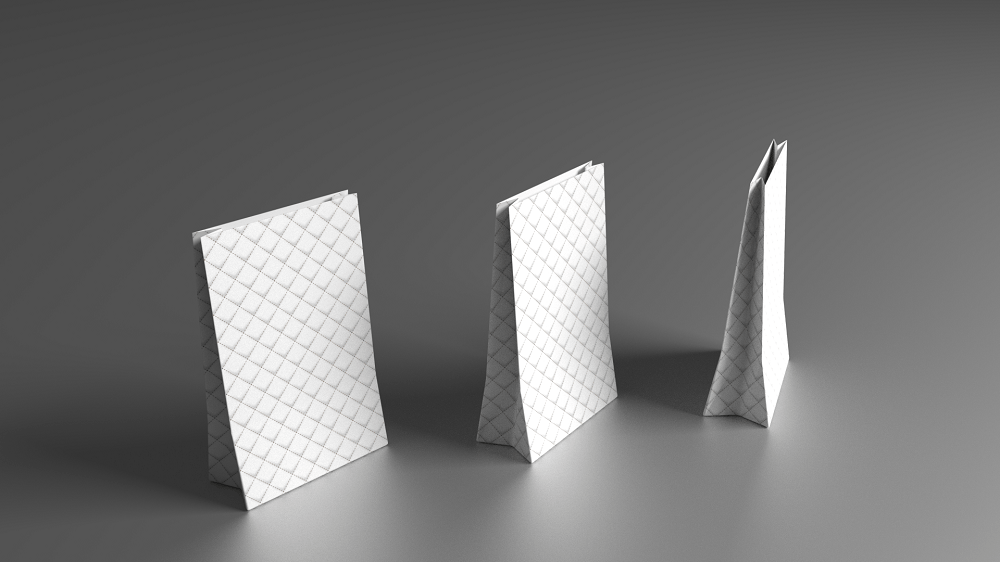

Paptic, though, claims that shoppers can enjoy the same sturdy benefits given by plastic bags without harming the environment using its Paptic paper-plastic hybrid material.

We look at the history of the company and how it plans to replace the use of plastic bags.

History of Paptic

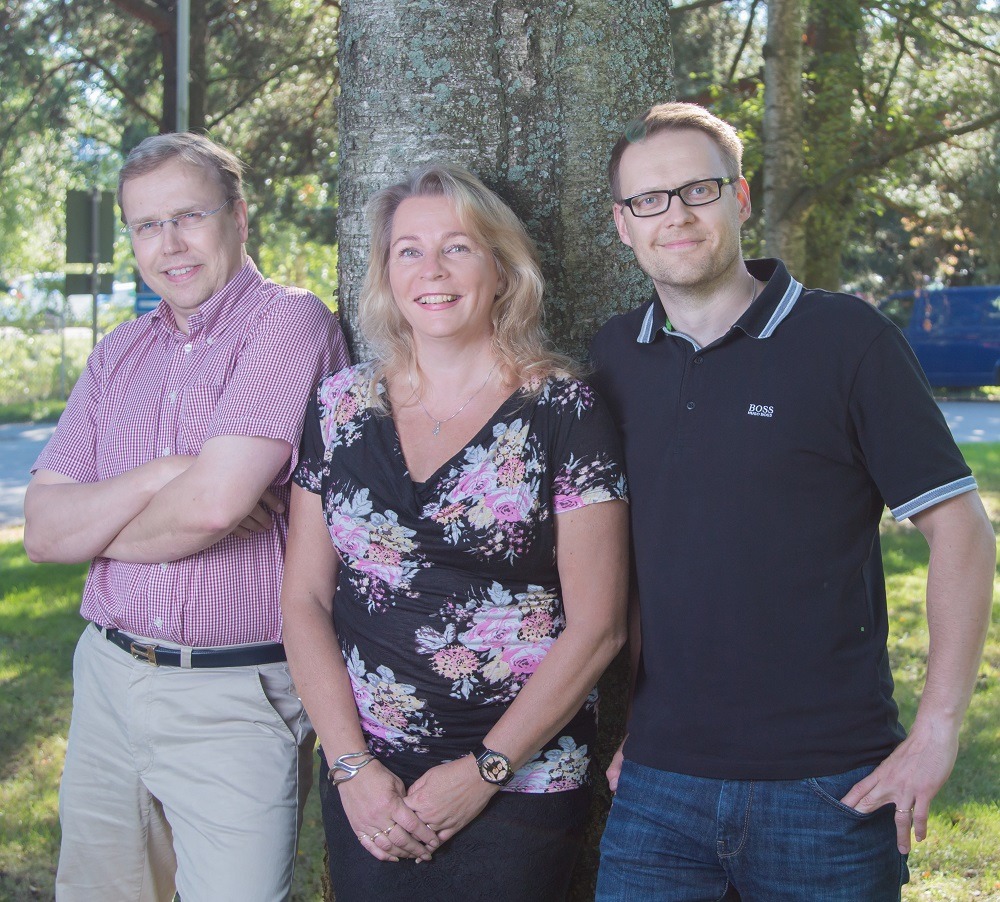

Paptic was founded in April 2015 by Finnish trio Esa Torniainen, Karita Kinnunen-Raudaskoski and Tuomas Mustonen, its current managing director.

The start-up is part of a seven-year research project that cost €10m (£8.6m) funded by Nordic research and technology company VTT, where Mr Torniainen and Ms Kinnunen-Raudaskoski were both previously employed, and where Mr Mustonen was vice-president.

When the company received its first amount of funding, €1.1m (£948,000) in 2015, Mr Mustonen said: “Our purpose is to help resolve a global environmental problem: the accumulation of plastic waste in the oceans and among marine life.

“If all the plastic waste already in the oceans was gathered up and put inside plastic bags, there would be around 15 bags per metre of the world’s coastline.”

In October 2016, Paptic pitched to investors at PitchFest during the European Forum for Industrial Biotechnology and Bioeconomy (EFIB), a community of businesses working in the bio-based economy, in Glasgow, Scotland.

The following month, it received a €2.2m (£1.8m) grant from the EU Commission’s Executive Agency for Small and Medium-sized Enterprises.

In 2018, the firm upscaled production to an industrial scale, and in 2020 it aims to have a new production machine up-and-running with a significantly larger capacity.

Based in Finland’s second biggest city Espoo, Paptic has 17 employees.

What does Paptic do?

Its name comes from the combination of the words “paper” and “plastic”, chosen by the company to reflect its claim that it offers a combination of the qualities of both materials.

As an alternative for plastic film, the firm uses fibre from wood pulp it collects from trees certified by conservation charities like the Forest Stewardship Council and the Programme for Endorsement of Forest Certification.

The firm also uses some bio-based, biodegradable, man-made fibre, and crucially does not use any fibres that traditionally make up plastic products.

To develop its products, Paptic uses normal paper machines but with its patented foam-forming technology, meaning it uses less water waste than the traditional paper-milling process, which does use water.

Sustainability manager Daniela Bqain tells Compelo: “Foam-forming is a novel technology that allows a significant amount of air to be mixed to a water-fibre suspension.

“It’s a more raw material, energy and water efficient process than the water-forming process which is used to produce conventional kraft paper.

“Foam-forming allows the improvement of product properties and also gives the opportunity to broaden the final product characteristics.”

The company claims its foam-forming technology can also be converted using the same machinery used to produce plastic, non-wovens and textiles.

Alongside bag production, Paptic hopes the new material could be used in the creation of packaging for foods, industrial and e-commerce products, as well as medical equipment.

Paptic’s support from industry

Former Finnish retailer Seppälä trialled the use of Paptic bags in its 92 stores across the Scandinavian country in June 2016, a year before it went bankrupt.

The supermarket chain’s then-marketing director Kati Kivimäki said at the time the innovation could “make a positive impact to the world”.

In 2017, Paptic conducted a presentation of its idea at an event hosted by the Bioeconomy Forum in Latvia.

The company mentioned a number of major companies that had expressed an interest in using the product.

Danish toy giant Lego said “it found that material interesting” and was “looking forward to seeing its real world testing”, while Swedish multi-national fashion retailer H&M said “this is too good a replacement of plastic bags”.

Ms Bqain said: “Paptic aims to become a company that everyone knows worldwide, and the company everyone wants to turn to when they are aiming to replace plastics or otherwise less environmentally-friendly packaging materials.”