Constantia Flexibles Group’s subsidiary Oai Hung (Vietnam) has invested in Bobst’s CL 850D laminator for high performance coldformed foil pharma packaging.

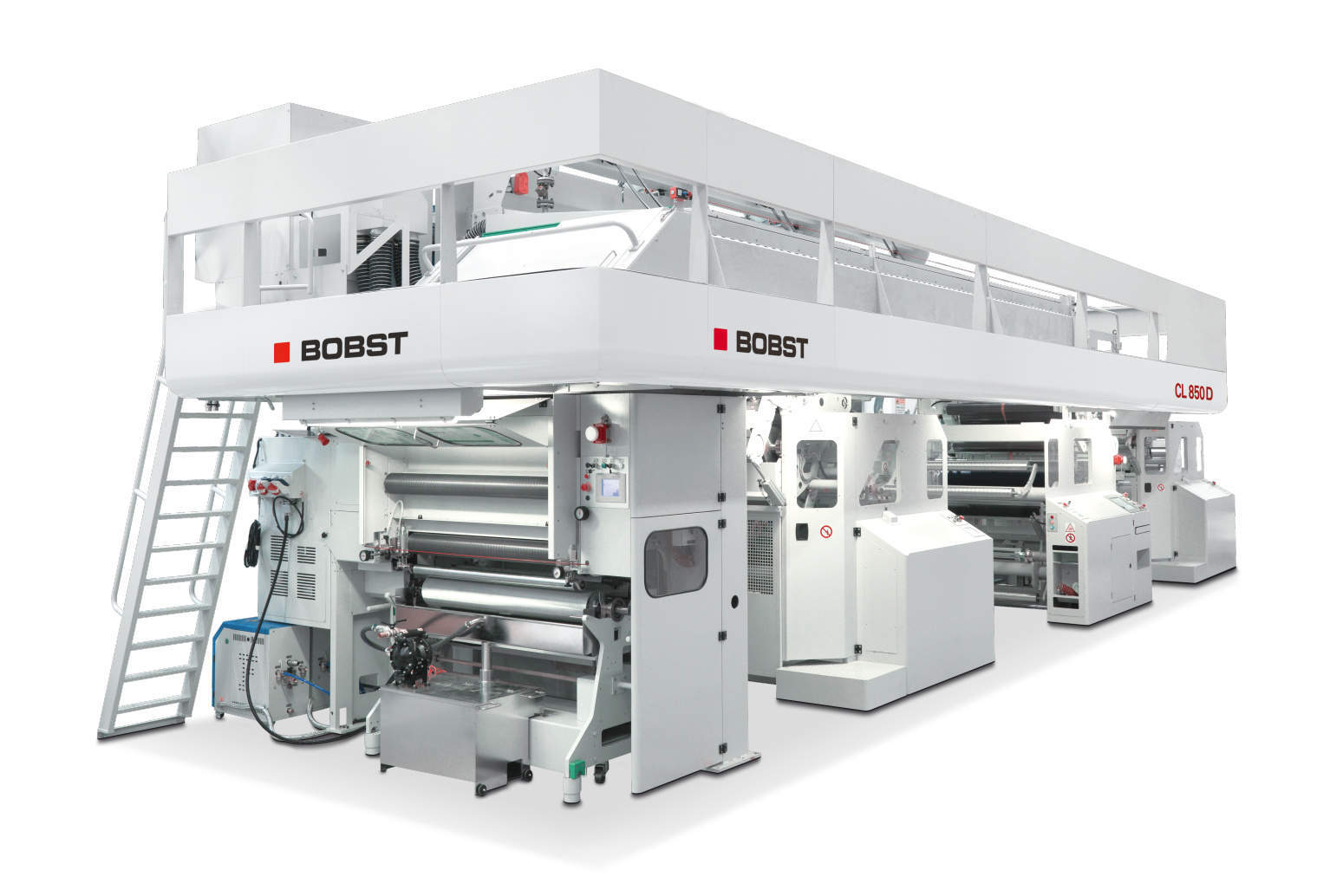

Image: The Bobst’ CL 850D laminator. Photo: courtesy of BOBST.

The investment in the CL 850D laminator is part of Constantia Flexibles’ strategy to expand the operations of Oai Hung Manufacturing, which is the group’s production site in Vietnam.

Oai Hung is engaged in the production of aluminium blister foil and rigid film for the pharmaceutical market, as well as foil-based lids for dairy packaging.

Planned to be installed in the cleanroom of Oai Hung’s production facility in Ho-Chi-Minh City in the second half of this year, the new laminator features a semi-flexo coating trolley and two-roller vertical solution to enable a higher coating speed.

The semi-flexo coating trolley is also expected to provide higher uniformity and a better coating profile across the entire web width, Bobst said.

Additionally, the two-roller vertical solution is designed to offer a higher coating speed that will ensure superior quality coating for either solvent-based adhesives or lacquers.

Constantia Flexibles Group Pharma Hub Cluster manager Rainer Huber said: “We trusted Bobst for this special project due to its know-how and experience in combining process expertise from both coating and lamination technologies.

“We are confident that the new CL 850D laminator will fulfil our requirements and prove Bobst once again to be a trusted and reliable partner for our lamination projects.”

The CL 850D machines also features an OPA-Alu-foil-PVC triplex compound structure, which involves ensuring 100% barrier to external agents and the resistance to stress and puncture of the material during the production processes.

The Alu-foil substrate is lacquered with an adhesion-enhancer primer before the start of the lamination process in order to ensure high delamination stability and additional protection of its barrier properties.

Additionally, the machine’s dryer involves both traditional and floatation type nozzles capable of offering maximum efficiency in evaporating the solvent from the lamination adhesive.

Constantia Flexibles is claimed to be the world’s fourth largest producer of flexible packaging. It employs about 8,300 people at 40 sites in 18 countries.