The MASTER DM5 is the most digitally automated press in the label market, with the highest print quality and productivity

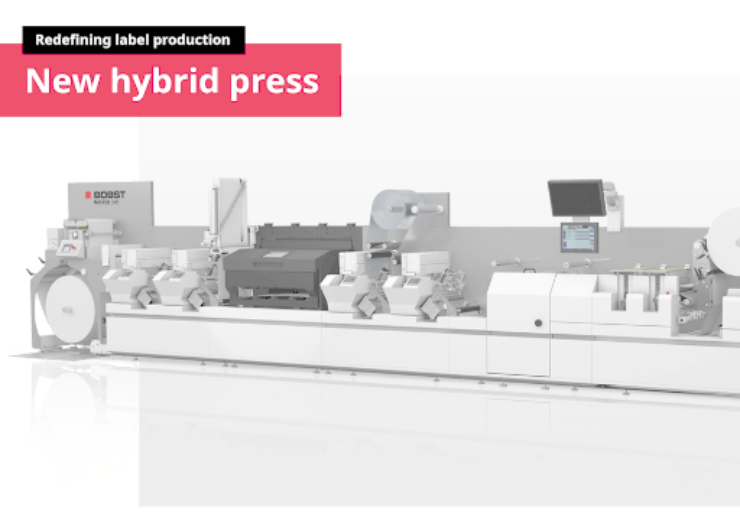

Image: Bobst has introduced new MASTER DM5 hybrid label press. Photo: courtesy of BOBST.

Bobst has expanded its label press portfolio with the introduction of new MASTER DM5 hybrid label press.

MASTER DM5, which combines digital and DigiFlexo printing in a single press, is claimed to be the most digitally automated press in the label market.

With Mouvent ink-jet digital technology inside, the new hybrid press provides flexibility to produce high-value labels with short job setup.

Bobst CEO Jean-Pascal Bobst said: “The MASTER DM5 is our first ever fully digitally integrated hybrid press and represents a new era in the production of self-adhesive labels with totally new standards of productivity and profitability.”

Features of Bobst’s new MASTER DM5 hybrid label press

Available with a convenient digital integration, the MASTER DM5 press offers easy and user-friendly access to digital print heads, as well as an automated set-up of multi-process operations.

The digital print engine of the press is made up of Mouvent’s advanced Cluster Technology, which integrates Fujifilm Dimatix Samba print heads. It is the basis of the entire range of digital printing machines developed by Mouvent, Bobst’s digital printing competence centre.

The simple to change Mouvent Cluster heads feature all-in-one fully integrated inking, conditioning and electronic circuits, which will help maintain the accuracy of print heads.

With an exclusive screening and digital front end (DFE) solution, Bobst’s new press also provides a wide digital colour gamut in digital printing, as well as accurate and easy to achieve digital color matching.

Ink-on-Demand (IoD) is an optional extra for DigiFlexo print units. The system, which eliminates ink trays and chambered doctor blades, performs fully automated washing of the print unit within one minute.

In addition, it has a full range of added value capabilities such as coatings, varnishes, tactile effects, 3d effects, hot stamping, cold foil, embossing, die cutting, punching, silk screen, flexo and digital variable data printing (VDP).

Bobst hybrid printing programme manager Federico D’Annunzio said: “Two of the greatest benefits of the MASTER DM5 are its productivity and reliability.

“It represents a total flexo-digital-converting integration, with non-stop productivity, and the highest press uptime in the industry.”

In May this year, Bridger Packaging, a UK-based manufacturer of cartonboard packaging, purchased two Bobst machines to increase capacity and drive efficiency.