The new press is equipped to operate at a maximum speed of 500 m/min and can be configured with either shaftless or shafted printing cylinders

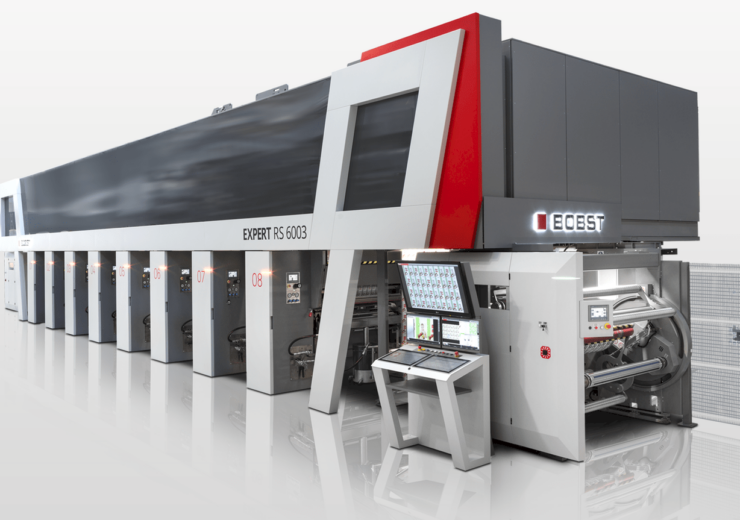

Bobst’s new generation gravure printing press. (Credit: BOBST)

Swiss company Bobst has introduced new generation gravure printing press, EXPERT RS 6003, for flexible materials.

The new press is designed to enable gravure converters to tackle dynamic market challenges while making press make-ready and job changeovers faster and easier.

It is capable of running at a maximum speed of 500 m/min, the press can be configured with either shaftless or shafted printing cylinders.

Bobst Italia gravure product line manager Jonathan Giubilato said: “Technology directed to bringing equipment and process performance always a step forward to the market current and future requirements is always on the move at BOBST.

“The flexible packaging market demands increasingly short run production, packaging versioning, lighter, thinner, recyclable solutions, global color consistency, then we are ready to support our converting customers with solutions delivering faster time to market, increased quality, productivity, agility and safety. Gravure technology is of course no exception.”

New press handles high-speed printing with both solvent and water-based inks

The EXPERT RS 6003 press is capable of handling high-speed printing with both solvent and water-based inks.

Additional features of the press include Flex Trolley, a service-type trolley designed to either stay onboard during printing or be removed after the print unit has been set-up to help reduce the minimum number of trolleys required for press operation.

In a press statement, Bobst said: “Configuration options extend to the inking system choice, to ensure the best quality output according to production requirements.

“The standard MPI (Multi-Purpose Inking) or the optional HSM (High Speed Metering) inking systems, both deliver consistent repeatable high-quality printing under any conditions and with all ink and solvent types.”

Earlier this year, Bobst has launched a new range of machines and solutions to better meet the requirements of its customers.