Apex North America has announced the addition of a 7M ALE Laser Engraving Machine and a 4.5M Full CNC Machine, as part of its expansion in the North American market.

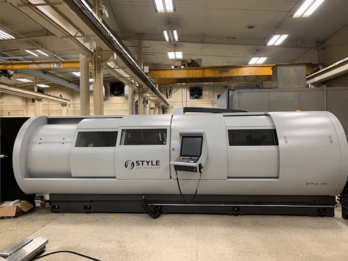

Image: Apex has added the latest 7M laser for the high demand of customers installing jumbo size presses aimed at corrugated and towel/tissue printing. Photo: Courtesy of Apex International.

Apex North America is a US-based manufacturer and marketer of metering rolls for applications such as printing and coating.

The company said that the expansion would allow precise application for every engraving Apex offers, including the globally patented GTT2.0, with improved tolerances down to .0002.

In addition, it has added the latest 7M laser for the high demand of customers installing jumbo size presses aimed at corrugated and towel/tissue printing.

Apex North America vice president Dave McBeth said: “The installation of this state-of-the-art laser underlines Apex’s commitment to the corrugated market and once again sees Apex making great leaps forward over our competition in how we can service customers within the corrugated anilox marketplace.

“This new ALE laser is the largest of its kind built in the world, allowing Apex North America to service the growing market of corrugated jumbo presses coming into the market.”

Apex North America plant manager Josh Scalise said: “The addition of these two new machines is a huge advantage for Apex North America.

“We’re able to service our customers even better than before with quicker turnaround times while still giving them the Apex quality that they’ve always received. It also creates more job opportunities, so we’re able to expand the North American team.”

Founded in 2000, Apex North America operates as a subsidiary of Apex Europe. In 2011, the firm has expanded its manufacturing plant in the US state of Pennsylvania, by adding 8,000ft² of space.

The company said that the Donora plant is expected to be one of the largest anilox production sites in North America, processing space for accommodating 12 lasers which can engrave both GTT and conventional hexcell anilox surfaces.

The new addition is also expected to meet the cleanroom fabrication standards, while the original building would be converted to include machining, repair and warehousing functions.