AMP Robotics, which serves the waste and recycling industry, now has a complete range of AI-powered solutions for materials recovery facilities (MRFs), along with a standalone, integrated facility solution to expand recycling infrastructure

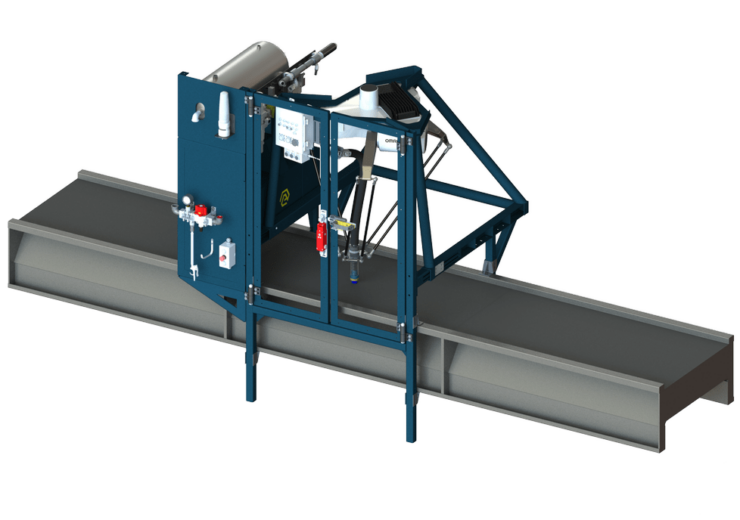

AMP Cortex-C will help in the material recovery for the retrofit of recycling facilities. (Credit: AMP)

AMP Robotics has launched AMP Cortex-C, a new artificial intelligence (AI)-based automated sortation solution and announced an integrated facility offering for new recycling infrastructure.

AMP Robotics, which serves the waste and recycling industry, now has a complete range of AI-powered solutions for materials recovery facilities (MRFs). It also has a standalone, integrated facility solution to expand recycling infrastructure.

AMP Cortex-C is said to be a small version of the firm’s AI-guided robotics system that brings the company’s AI expertise and robot technology to more facility locations. It also adapts to space constraints.

With a small-footprint, easy-to-install robot, the technology provides a consistent, reliable sortation solution to locations that are hard to staff or where current labour can be redistributed.

According to the company, the solution uses its robot technology, AI for object recognition, and patented control software consistent with AMP Cortex units.

The firm has designed the Cortex-C using experience from more than 300 installations.

Adaptable to a range of conveyor belt sizes, angles, and configurations, Cortex-C can fit into more locations to increase sortation points and material recovery within facilities, the firm claimed.

AMP technology solutions group GM Jeremy Neigher said: “The expertise we’ve built in recycling technology has enabled us to expand where and what we can sort so we can bring the benefits of AI-driven automation to more locations in more facilities.

“We’re committed to innovating so we can deliver the latest advancements in AI and automation to our customers to increase their profitability and improve their bottom line.”

Additionally, the robotics company has introduced new AI – Advanced Targeting (AT) algorithms that leverage machine learning to find the optimal grip area for each item its system identifies.

The AI-driven software is available for all Cortex and Cortex-C units, the robotics company said.

Leveraging its experience and learnings in secondary sortation to next-generation facilities, the company will design, build out, operate, and service customers. The facilities will aim at single-stream and secondary feedstocks.