Swiss technology and automation provider ABB has launched Winder Performance Optimization, a new digital solution for paper manufactures who seek to maximise capacity and productivity.

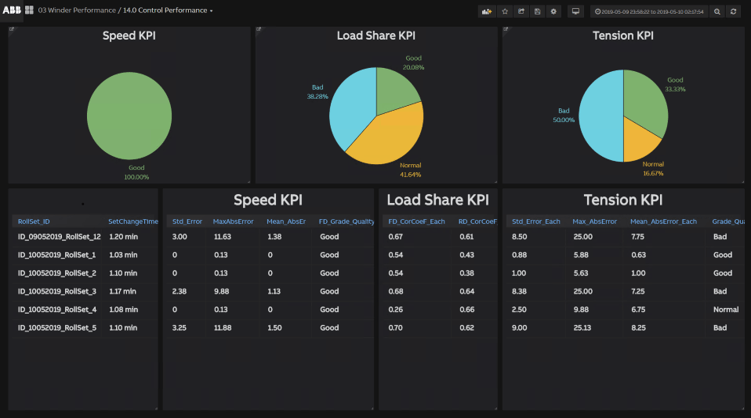

Image: ABB Winder Performance Optimization continuously monitors and analyzes KPIs to enable preventive maintenance and increased uptime. Photo: Courtesy of ABB.

Forming part of ABB’s Ability Performance Optimization solution suite, Winder Performance Optimization is set to enable papermakers to maximize asset performance, convert to different paper grades and enhance machine speed, without replacing existing winders.

The new Winder Performance Optimization solution works by evaluating winder performance, executing improvements, monitoring performance and optimising productivity by applying online calculations that continuously adjust winder acceleration and deceleration targets.

Apart from being cost-effective and easy to execute the winder, the solution also offers many benefits through optimising existing winders.

The new solution is designed to reduce the bottlenecks caused by larger, faster machines in the production process and enhances winder capacity without compromising quality.

ABB Digital Solutions global product manager Shankar Singh said: “We understand the importance for papermakers to ensure their existing winders are able to handle demands of different grades, various roll orders with high quality and productivity improvement needs.

“Our goal with this product is to help mills get improved productivity out of their existing winders, without the need to invest heavily in new equipment. With several existing installations around the world, we are pleased that papermakers are already realizing the benefits of improved winder performance and productivity by utilizing our patented solution’s unique ability to continuously adjust winder speed.”

Swiss technology and automation firm said that the solution feeds energy back into the system in regenerative mode, providing further energy efficiency for the mills.

In addition, the Winder Performance Optimization solution is capable of monitoring and improving roll set quality, and improving machine reel capacity.

Furthermore, the solution features local and remote dashboards that enable instant, straightforward data visualisation, for analytics and daily analysis of performance, control and roll set performance carried out by ABB experts.

With about 147,000 employees and operations in more than 100 countries, ABB has four businesses: Electrification, Industrial Automation, Motion, and Robotics & Discrete Automation.